03 Sep UV Resistance Of Aluminium Composite Panels For Exterior Curtain Walls

Table of Contents

Aluminium composite panels offer excellent UV resistance, making them an ideal choice for exterior walls such as curtain walls. The PVDF coating provides strong protection against harmful UV rays, helping the panels maintain their bright color for many years. This coating also prevents fading and chalking caused by sun exposure. Additionally, the aluminium layers reduce thermal stress, keeping the panels stable and looking great over time. These features ensure the panels remain durable and secure, lasting for many years even under constant sunlight.

PVDF coating enhances UV resistance, keeping panels shiny and colorful for years.

Panels resist bending, fading, and chalking from prolonged sun exposure.

Aluminium layers strengthen panels and provide additional UV resistance.

Key Takeaways

Aluminium composite panels with PVDF coatings block UV rays well. They keep their color and strength for many years. Good coatings and aluminium layers protect panels from fading. They also stop cracking and damage from sunlight and weather. Regular cleaning and checking help keep panels looking nice. This also keeps their UV resistance strong, especially in sunny or dirty places. Picking high-quality panels with strong coatings saves money over time. This is because you need fewer repairs and replacements. Panels fade faster in sunny, coastal, or dirty places. So, extra care and the right coating are important.

UV Resistance Overview

Why UV Matters

Ultraviolet (UV) resistance is very important for aluminium composite panels on outside curtain walls. When panels get a lot of sunlight, UV rays can hurt the chemical bonds in the panel’s polymer matrix. This makes free radicals, which mix with oxygen and start photo-oxidation. Over time, this breaks down the material, makes it weaker, and changes its color.

UV resistance stops fading, color change, and weakening of curtain wall materials in the sun. Panels with good resistance keep their color and strength after being in the sun for a long time. This is extra important for buildings in sunny places or where people see them a lot, because they need to last and look nice.

Here are the main ways UV radiation affects aluminium composite panels:

UV rays break the molecular bonds in the polymer matrix and make free radicals.

Free radicals mix with oxygen and cause photo-oxidation, which breaks down the material.

Water and heat make the damage happen faster by letting more oxygen reach the material.

UV damage makes the panels lose strength and stiffness.

The surface can change color and get damaged, which hurts how it looks and works.

The structure can get weaker, which makes cracks and breaks more likely.

Choosing panels with high UV resistance helps curtain walls stay strong and look good for a long time. Better resistance usually needs special coatings like PVDF, which protect from strong sunlight and lower the need for repairs.

Impact on Appearance

How curtain walls look depends a lot on how well they handle UV light. If they do not have good protection, panels can fade, lose shine, and crack. These problems make the building look worse and show that the material is getting damaged inside.

Aluminium composite panels with PVDF coatings are very good at stopping UV damage. This coating keeps the panels from fading or breaking down, even after many years. The aluminium layer also bounces back some UV rays, so less hits the resin, which helps keep the color and strength.

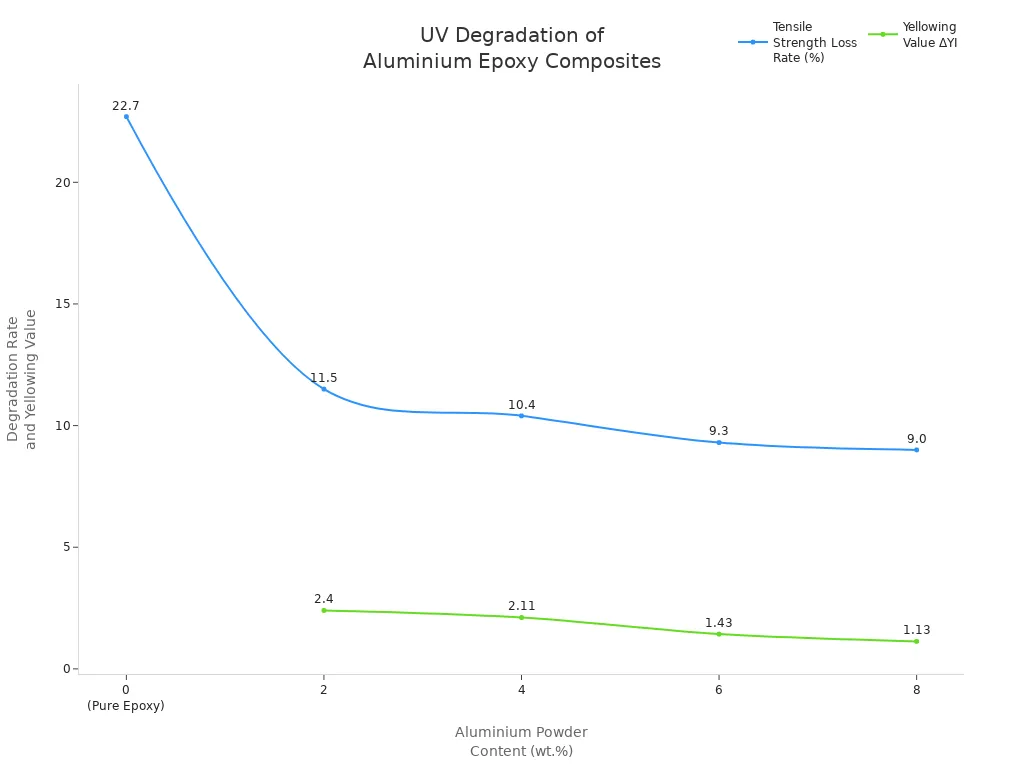

The table below shows how much aluminium powder in epoxy composites changes strength loss and yellowing after 100 days of UV light:

Aluminium Powder Content (wt.%) | Tensile Strength Loss Rate after 100 days UV Aging (%) | Yellowing Value ΔYI after 100 days UV Aging |

|---|---|---|

0 (Pure Epoxy) | 22.7 | N/A |

2 | 11.5 | +2.40 |

4 | 10.4 | +2.11 |

6 | 9.3 | +1.43 |

8 | 9.0 | +1.13 |

This table shows that more aluminium makes UV resistance better. It lowers strength loss and yellowing. Panels with better resistance keep their color and finish longer, which is important for buildings that need to look new and nice for a long time.

Note: Not all aluminium composite panels have the same UV resistance. The coating type, like PVDF, really matters for stopping fading and damage from UV rays.

Causes of Fading

UV Exposure

Aluminium composite panels on curtain walls get lots of sunlight. UV rays from the sun hit the panels every day. This breaks down the color in the surface coatings. The panels start to lose their bright color and can look patchy. Sometimes, a white powder forms on the surface. Fading begins when UV rays damage the coating’s chemical structure. Over time, the panels lose their shine and brightness.

Manufacturers use tests like ASTM D2244 to check color. They use ASTM D4214 to see how much chalk forms. Florida Weathering Tests show how panels age in sunlight. PVDF coatings help panels fight UV damage. These coatings keep over 80% of their shine and color after ten years outside. Polyester coatings do not last as long in strong sun. They may start to fade after three to five years. Panels on south-facing walls or in hot, sunny places fade faster.

Tip: Pick panels with PVDF coatings for better protection. They work best in places with lots of sun and UV rays.

Environmental Effects

The environment also affects how fast panels fade. High heat and strong sun cause stress and make fading happen faster. Humidity and water can weaken the coatings. This makes the color fade and the panels not last as long. Pollution and dust make panels look dull. They also make the coatings work less well.

Panels in dirty city areas or near the sea fade more. Heavy rain, very hot or cold weather, and stains from water cause more damage. Cleaning and taking care of the panels helps stop fading. Aluminium composite panels have smooth surfaces and special layers. These stop water from getting in and keep out mold and rust. These features help panels stay strong and look new for a long time.

Note: Check and clean panels often to protect them. This helps keep their color and strength.

Coatings and Protection

PVDF Coating

PVDF coating is the top choice for stopping UV damage. This special coating makes a strong shield on the panel. It keeps panels looking new for many years. PVDF has strong carbon-fluorine bonds. These bonds help block harmful rays. They stop fading, chalking, and erosion.

Tests in labs and outside show PVDF works well:

Water slides off easily, so panels stay clean and dry.

In southern Florida, PVDF panels kept their color for 21 years.

PVDF absorbs little UV energy, so colors last longer.

Acrylic resin coatings faded and wore out after only 7 years, but PVDF panels stayed bright.

Fluoropolymer coatings like 70% PVDF last a long time. Tests in Florida show these coatings keep their color and resist chalking for decades. Polyester coatings lose their look after just a few years. PVDF coatings use layers with clear topcoats. These layers give extra protection. They help stop dirt and make panels stronger against weather. PVDF is the best choice for architects who want panels that last and need little care.

PVDF-coated aluminium composite panels give the best protection from UV rays, pollution, and bad weather. They keep their color and finish, even in tough places like near the sea or factories.

Here is a cost comparison for different coatings:

Panel Type | Approximate Cost (per sq. ft.) | Key Features and Cost Drivers |

|---|---|---|

PVDF Coated Panels | Strong UV resistance, better weather protection, lasts longer | |

Nano Coated Panels | $10 to $18 | Cleans itself, great UV protection, good for harsh places |

Polyester (PE) Coated Panels | $3 to $6 | Basic coating, not as tough, best for inside use |

PVDF-coated panels cost more at first. But they save money later because you do not need to fix or replace them as often.

Resin and Chromate Layers

Resin and chromate layers work together to make panels stronger. Chromate coatings protect the aluminium from rust and damage. This layer acts like a shield. It stops rust and keeps the metal safe.

Resin coatings, like PVDF resin or powder coatings, make a waterproof cover. These coatings fight sunlight, water, and pollution. They help panels keep their color and smooth surface for years. UV-cured hybrid coatings mix organic and inorganic parts. They keep their shine and stay strong after UV hits them. These coatings were first used on airplanes. Now they help building panels last longer and look good.

These layers stop rust, block UV damage, and help panels last longer. Resin and chromate layers give panels the strength and protection needed for outside curtain walls.

Panels with good coatings need less cleaning and no repainting. This helps buildings be greener and saves money over time.

Modern coatings help the environment too. Many aluminium composite panels use recycled materials. They can be recycled when they are old. The coatings reflect sunlight, which lowers heating and cooling costs. Makers now offer coatings with low VOCs. This helps buildings meet green rules like LEED.

New coatings include nano-coatings that stop scratches and rust. Some coatings clean themselves and fight graffiti. These new ideas help panels last longer and make them easier to take care of.

Quality and Performance

High-Quality vs. Low-Quality Panels

Panel quality changes how well they work outside. Good aluminium composite panels have special coatings. These coatings help them last in bad weather and keep their color. PVDF coatings are the best for blocking UV rays and lasting a long time. They use a strong resin that makes tight bonds. This helps the panels stay colorful and smooth for many years. Makers often give 15 to 20 year warranties. This shows they trust their panels to last a long time.

Cheaper panels use polyester coatings. These coatings do not block UV rays as well. They also do not protect from weather as much. They cost less, but they fade and lose shine quickly. Polyester-coated panels are better for inside or places with little sun. If you use them outside, they fade fast and need more repairs.

Coating Type | UV Resistance and Durability Characteristics | Typical Application Context |

|---|---|---|

PVDF Coating | Great UV protection, strong in bad weather, keeps color for years; often has 10+ year warranties. | Best for high-quality panels used outside. |

Polyester Coating | Okay UV resistance, not as tough, costs less. | Good for lower-quality panels inside or in gentle weather. |

Anodized Coating | Hard, stops rust, good at blocking UV rays. | Used in tough or seaside places. |

Tip: Pick top aluminium composite panels with PVDF coatings. They work better and need less fixing over time.

Common UV Issues

Panels in the sun can get many UV problems. Sunlight for a long time can break gaskets and sealants. This can make leaks and lower how well the panel keeps out weather. Some panels change color if they use indoor coatings outside. This mistake makes panels look old and patchy fast.

Other problems happen when the wrong glue is used. If makers use the wrong adhesives, panels can peel or fall apart in the sun and heat. These problems cost a lot to fix and make the panels not last as long.

Sunlight breaks gaskets and sealants, so leaks happen.

Using indoor coatings outside makes panels fade and change color fast.

Wrong adhesives make panels peel or fall off.

UV-Related Issue | Description | Cause / Explanation |

|---|---|---|

Discoloration and Decoloration | Outdoor panels with indoor coatings get old and change color fast. | Indoor coatings cannot handle sunlight outside. |

Adhesive Failure (Peeling) | Using the wrong glue outside makes it fail in the sun. |

Makers who use good coatings and the right glue stop these problems. They also give long warranties, sometimes up to 20 years, for UV and color. This helps building owners worry less and keeps their buildings looking good.

Maintenance Tips

Cleaning

Cleaning

Cleaning aluminium composite panels often helps them look new. It also keeps their UV resistance strong. Owners should use gentle soap mixed with warm water. Soft cloths or sponges are best so the coating does not get scratched. Clean small parts at a time. Do not clean when the sun is very bright. Strong chemicals like potassium hydroxide or caustic soda can hurt the paint. They can also cause rust, so never use them.

Tip: You must clean panels by hand. Rain cannot wash away all the dirt and debris that can harm the panel’s surface.

The table below shows how often to clean panels in different places:

Environment Type | Cleaning Frequency |

|---|---|

Urban and Industrial Zones | |

Coastal or High-Pollution Areas | Every 3 to 6 months |

Interior or Low-Dust Regions | Annually |

Inspection

Checking panels often helps find problems early. Building managers should look at panels at least once a year. In places with more dirt or bad weather, check every three months. Focus on the joints and edges. These spots get damaged first. Look for color changes, peeling, bubbles, or water marks.

Watch for fading or color changes, which can mean UV damage.

Look for peeling or bubbles, which may show coating or glue problems.

Check for water marks, which can mean leaks or sealant problems.

Note: Finding problems early stops bigger repairs and helps panels last longer.

Recoating

Recoating brings back the panel’s UV protection and looks. Start by cleaning with gentle soap and a soft cloth. Sand any damaged spots until smooth. If there are dents or scratches, use special fillers to fix them. After fixing, put on a primer that matches the panel. Paint several thin layers of good paint for even color. When dry, polish to make it shiny again. Add a final UV-resistant sealant to protect from the sun.

Fixing small problems fast stops them from getting worse.

Coatings and sealants help repairs and panels last longer.

Always follow the maker’s care tips and ask experts for the best results.

Where Fading Occurs

High-Exposure Areas

Fading usually starts where the sun hits the most. Curtain walls on the south and west sides get the strongest sunlight. These spots get more rays, so panels lose color faster there. Corners, edges, and places near windows fade first. They get more light and heat than other spots. Rooftop panels and those above open spaces have little shade. This makes them more likely to fade.

Building managers see that these sunny areas need more care. They might notice color changes or dull spots sooner here. Chalking can also show up faster in these places. Checking these panels often helps find problems early.

Tip: Clean and check panels in sunny spots more often. This keeps the building looking bright and fresh.

Climate Impact

The weather in an area affects how fast panels fade. Different places have different problems:

Tropical places are hot and wet with strong sun. Panels here fade faster if not protected well.

Temperate places have less sun and lower humidity. Panels fade slower in these areas.

Coastal places have salt and water, which can damage panels faster.

Big changes in temperature can stress panels, but composite cladding stays in shape better than some metals.

Makers add special stabilizers to help panels handle tough weather. Panels that resist water are very important in tropical and coastal places. Picking the right panel for the local weather helps keep color and finish for many years.

Aluminium composite panels are very strong and last a long time. They also protect buildings from the sun’s UV rays. PVDF coatings help stop fading and color changes. This keeps buildings looking nice for many years. Owners do not need to do much work to keep them clean. This saves money over time. Good panels can handle bad weather and still look good for a long time.

Benefit Category | Description |

|---|---|

Panels do not break, scratch, or fade, even in tough weather. | |

Low Maintenance | Special coatings mean you do not need to clean them often. |

Aesthetic Longevity | UV-resistant finishes keep the color and look nice for many years. |

FAQ

Are aluminium composite panels completely UV resistant?

Aluminium composite panels with PVDF coatings resist UV rays well. They do not stop every UV ray. But they keep their color and strength for many years. Panels without good coatings can fade or get weak faster.

How often should building owners clean exterior panels?

Experts say to clean panels every 6 to 12 months in cities. In coastal or dirty areas, clean every 3 to 6 months. Cleaning often helps panels stay shiny and keeps their UV protection strong.

What is the best coating for UV protection?

PVDF coating gives the best UV protection. It helps panels stay colorful and strong for a long time. Polyester coatings are better for inside or places with gentle weather. PVDF is the top choice for outside walls.

Can faded panels be restored?

Owners can fix faded panels by adding new UV-resistant paint. First, clean and sand the surface to get it ready. Getting help from experts makes the panels look better and last longer.

Cleaning

Cleaning