27 Sep What Materials Make Up an ACP Facade?

Table of Contents

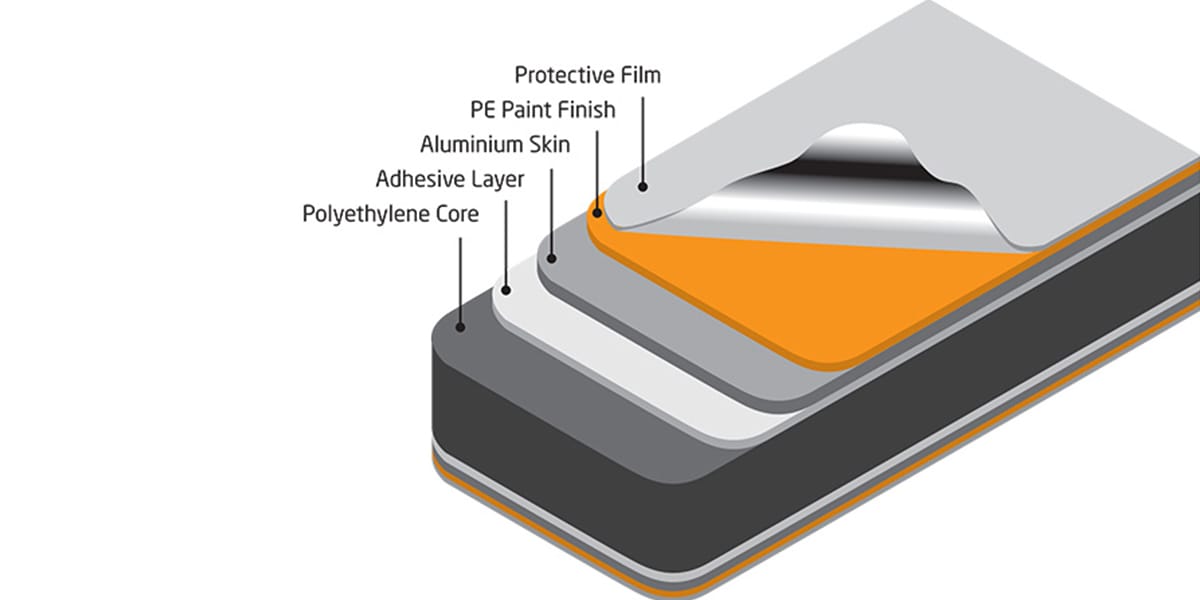

When you ask, What is an ACP facade?, you learn it has two aluminum sheets. There is a middle core made from PE, LDPE, FR, or mineral-filled stuff. It also has strong glue layers. Each part helps with safety, strength, and looks. The aluminum sheets make the facade strong and protect it from weather. This makes it hard to break and helps it last longer than other materials. The core can change how safe it is, especially if it uses PE, which can catch fire more easily. You get layers that make it safer and help it handle bad weather.

Key Takeaways

ACP facades have two aluminum sheets and a core. The core can be PE, LDPE, FR, or mineral-filled. This makes the panels strong and tough.

Picking the right core is very important for safety. Fire-resistant and mineral-filled cores protect better than polyethylene cores.

ACP panels can handle bad weather. They can last up to 20 years if you take care of them. Cleaning them often keeps them looking good and strong.

Using ACP panels helps save energy in buildings. They lower heating and cooling costs. They also keep indoor temperatures steady.

ACP panels come in many colors and finishes. This lets people make creative designs. The panels look nice and do not add much weight.

What Is an ACP Facade?

An ACP facade is a building’s exterior cladding system made of Aluminum Composite Panels (ACP). These panels are lightweight, durable, and weather-resistant, consisting of two thin aluminum sheets bonded to a central core, typically polyethylene or a mineral filler. ACP facades are used for both building exteriors and interiors, offering a modern and versatile aesthetic with a wide variety of finishes like solid colors, wood grain, or metallic looks.

Aluminium Composite Panels Structure

Aluminium composite panels look like a sandwich. Two aluminum sheets are on the outside. The core is in the middle. This design makes acp panels last long and bend easily. You can see the usual thicknesses in the table below:

Panel Thickness | Recommended Application Area | Notes and Characteristics |

|---|---|---|

2-3 mm | Indoor/light projects | Good for inside walls, ceilings, and room dividers; not for outside or heavy jobs. |

4 mm | Outdoor and facade applications | Works for many jobs; good for outside walls, signs, and building fronts. |

5 mm and above | High-rise curtain walls, large outdoor projects | Best for strong places; often used with thicker skins or fire-safe cores. |

Thicker panels are better for building facades. They give more protection and strength. Aluminium composite panels can take hits and do not bend out of shape.

They are tough, so you can bend them without ruining the surface.

In sandy places, acp cladding does not get damaged easily.

This design helps your facade stay safe and look new for a long time.

Core Materials in ACP Panels

The core inside aluminium composite panels changes how safe and heavy they are. You can pick from PE, LDPE, FR, or mineral-filled cores. Each one has different chemicals and safety levels. The table below shows what is in each core:

Core Type | Chemical Composition |

|---|---|

LDPE | Low-Density Polyethylene (LDPE) |

Fire-resistant (FR) | Fire-resistant mineral core with magnesium hydroxide |

Mineral-filled | 70% calcium hydroxide, magnesium hydroxide, and other inorganic materials, 30% polymer |

Mineral-filled cores make acp panels heavier and safer. Polyethylene (PE) core panels are lighter, about 2.5 lbs per square foot. They are easy to move. Fire-retardant core panels are a bit heavier because they use thicker materials. You should think about these things when picking acp cladding for your building.

Adhesive Layers

Adhesives hold the layers of aluminium composite panels together. There are different types used in acp panels:

Methacrylate adhesives

Polyurethane adhesives

Structural adhesives

Manufacturers use strong adhesives to stick aluminum, engineered wood, and fiberglass together. Foam adhesive and structural adhesive are common for acp cladding. The right adhesive thickness keeps your facade strong. The best thickness is between 0.05 and 0.15 mm. If you use too much or too little, the bond is weak. You want your acp panels to last, so this is important.

When you ask, “what is an acp facade?”, you see each layer matters. Aluminum sheets, core, and adhesive all help. Your facade can handle weather, hits, and time. Knowing about these materials helps you make good choices for acp cladding.

Exterior Applications

Weather Resistance

Weather Resistance

You want your building to stay safe from rain and storms. ACP panels protect buildings outside. Their layers stop water from getting in. They also keep rust from starting. ACP panels can handle wet weather and big temperature changes. Many builders pick ACP for outside walls because it lasts longer than other choices.

Here is a table that shows how long ACP panels last:

Quality of Panels | Lifespan Range |

|---|---|

Standard Panels | 10 years |

High-Quality Coatings (e.g., PVDF) | 15 to 20 years or longer |

If you use better coatings, your walls look new for years. These panels are simple to put up, so you save time. ACP panels keep their color and shape, even when the weather changes fast. You do not have to worry about cracks or fading. This makes ACP a good pick for outside projects.

Tip: Clean ACP panels often to help them stay strong and look nice.

Energy Efficiency

ACP panels help you use less energy in your building. They keep the inside temperature steady. You do not need as much heating or cooling. This means your energy bills go down. ACP panels block heat from coming in or going out. Your building stays comfy in every season.

When you use ACP for outside walls, your building is more green. You spend less on power because you do not need as much air conditioning or heat. Using ACP in big buildings saves a lot of money over time. You get a strong wall and pay less.

ACP panels are easy to put up, so you finish faster. You also help the planet by saving energy. ACP panels make your building look modern and work better outside.

Material Properties

Durability

You want your building to last a long time. Aluminium composite panels help protect buildings. They have a special structure. Two aluminum sheets cover a core in the middle. This makes acp panels strong and tough. These panels do not dent or break easily. Your facade stays smooth and safe.

Here is a table that shows how strong aluminum sheets are in acp cladding systems:

Property | Test Method | Test Result |

|---|---|---|

Flexural Strength | ASTM D790-10 Procedure A | |

Flexural Modulus | ASTM D790-10 Procedure A | 21130 MPa |

Tensile Strength | ASTM E8/E8M-11 | 52.2 MPa |

Aluminium composite panels do not rust in bad weather. You can use them in rainy, sunny, or coastal places. They block UV rays, so colors stay bright for years. ACP panels need less care than stone or glass. You do not have to worry about cracks or stains like with other materials. ACP cladding keeps your building looking new with little work.

ACP panels are made to handle tough weather, UV rays, and rust.

Stone can crack or stain if you do not take care of it, but acp cladding stays strong.

You save time and money because acp panels need less care.

ACP cladding is light, so it is easy to put up. You can cover big areas without adding much weight. This helps you follow safety rules and finish your project on time.

Tip: Pick high-quality acp panels for the best strength and value.

Fire Safety

Safety is very important for buildings. The core inside acp panels changes fire risks. Polyethylene (PE) cores can burn fast and are not as safe. Fire-resistant (FR) and mineral-filled cores protect better and help you meet safety rules.

Here is a table that compares fire safety for different core types in acp cladding:

Core Type | Core Material | Typical Applications | Regulatory Compliance | |

|---|---|---|---|---|

Polyethylene (PE) | Plastic (PE) | Low; burns easily | Inside use, short buildings | Often does not pass strict rules |

Fire-Resistant (FR) | Mineral-filled | Medium to high; stops fire better | Taller or riskier buildings | Passes tougher fire safety rules |

A2 Core | Mineral-based | High; does not burn | Big projects needing high safety | Passes strict standards |

A1 Core | Mineral-based | Highest; does not burn | Large, important projects | Best fire safety compliance |

You must follow safety rules when you pick acp cladding. New building codes do not allow materials that burn in tall buildings. EN 13501-1 A1 and A2 ratings help you choose. Many cities now want old buildings to be safer from fire.

Manufacturers keep making acp panels safer. They use aluminum and mineral cores that do not burn. You can trust new acp cladding to protect your building and the people inside.

New rules need better fire safety.

Strong acp panels are used in public buildings and tall towers.

ACP cladding with A2 or A1 cores helps you meet the strictest safety rules.

Aesthetics

Looks are important for every building. Aluminium composite panels give you many choices for design. You can pick from many colors, custom shades, shiny finishes, and special effects. ACP panels can look like wood, stone, or marble. You get the beauty of natural materials but with less weight.

Here is a table that shows some popular color and finish choices for acp panels:

Color/Finish Type | Description |

|---|---|

Standard Colors | |

Custom Colors | Unique shades to match your project theme. |

Metallic Finishes | Looks like gold, silver, or other metals for a luxury feel. |

Special Effects Finishes | Pearlescent and iridescent coatings that change with the light. |

Textured Surfaces | Woodgrain, stone, and other textures for a natural look. |

Digital Printing | Detailed designs and branding for creative facades. |

Eco-friendly Finishes | Sustainable options that look good and help the environment. |

Wood texture gives your building a warm, natural look.

Stone texture adds character and strength.

Marble texture looks fancy but costs less.

Metallic and shiny finishes make your building stand out.

You can use acp cladding for any building style. The light panels let you make bold shapes and curves. ACP panels keep their color and finish for years, so your building always looks fresh. You can meet your design and safety goals with the right acp cladding.

Note: ACP panels help you balance safety, strength, and looks in every project.

Core Comparison in Facade Panels

PE vs. FR vs. Mineral-Filled

PE vs. FR vs. Mineral-Filled

Aluminium composite panels have three main core types. These are PE, FR, and mineral-filled. Each core changes how the panels work. They also affect how safe your building is. You need to know how each core reacts to fire. You also need to know if they meet safety rules.

Core Type | Suitability for High-Risk Environments | |

|---|---|---|

PE (Polyethylene) | Lower (flammable) | Less suitable |

FR (Fire-Retardant) | Higher (fire-resistant) | More suitable |

Mineral-Filled | Enhanced fire safety | Highly suitable |

PE cores cost less but can catch fire easily. FR cores have chemicals that slow down fire. Mineral-filled cores give the best safety. They meet strict rules for buildings. You see mineral-filled panels in tall buildings and busy places.

Panel Type | |

|---|---|

PE Core | Generally more cost-effective |

FR Core | More expensive due to fire-retardant properties |

Mineral-Filled Core | Priced higher due to fire-resistant capabilities |

FR and mineral-filled panels cost more money. But they keep buildings safer and follow more rules. You should think about risks before you pick a panel. You also need to know what kind of facade you want.

Safety and Compliance

You must follow rules when you pick acp cladding. Building codes say every layer must pass fire tests. The National Construction Code (NCC) and AS1530 set these rules. You need proof that your panels are safe.

To be a ‘bonded laminated material’ under this rule, each layer must not burn. This means the aluminum and the core must pass the AS1530 Combustibility Test. NCC needs test reports or certificates to show your panels are safe.

Insurance companies check if acp panels can burn. If you use PE cores, insurance costs may go up. After big fires, insurers want safer panels. They want panels that do not burn or have test approval. You should talk to your insurer early. This helps you make sure your panels meet rules and keep people safe.

Insurance companies look at panel safety before giving coverage.

You pay less for insurance with mineral-filled or FR core panels.

New buildings need panels that pass tough safety rules.

When you pick acp panels, you must think about cost, safety, and rules. The right panels protect your building and help you follow all laws.

When you pick acp panels, you want them to be safe. You also want them to last a long time and look nice. ACP panels let you change designs easily. They help keep buildings warm or cool. You do not need to spend much on repairs. The best acp core makes your building safer. It also saves money over the years. Architects like acp panels because they do not burn fast. They also come in many colors.

Feature | Benefit |

|---|---|

Safety | Fire-resistant acp panels |

Durability | |

Aesthetics | Creative acp facade designs |

You need to think about the core type before you use acp outside. Make sure your acp panels follow safety rules. Pick good materials so your building stays safe and works well for a long time.

FAQ

What is the main benefit of using ACP panels for building facades?

You get strong protection from weather and impacts. ACP panels last longer than many other materials. You can choose from many colors and finishes to match your building style.

Are ACP panels safe for tall buildings?

You should use ACP panels with mineral-filled or fire-retardant cores. These panels meet strict fire safety rules. PE core panels do not pass most codes for tall buildings.

Tip: Always check local building codes before you choose ACP panels.

How do you clean ACP facades?

You can clean ACP panels with mild soap and water. Use a soft cloth or sponge. Avoid harsh chemicals and rough brushes. Regular cleaning keeps your facade looking new.

Can you recycle ACP panels?

Yes, you can recycle ACP panels. The aluminum sheets and some core materials can be reused. Recycling helps you reduce waste and protect the environment.

Material | Recyclable? |

|---|---|

Aluminum | ✅ Yes |

Mineral Core | ✅ Yes |

PE Core | ♻️ Sometimes |

Do ACP panels help save energy?

You get better insulation with ACP panels. They help keep your building cool in summer and warm in winter. This lowers your energy bills and makes your building more comfortable.

Weather Resistance

Weather Resistance PE vs. FR vs. Mineral-Filled

PE vs. FR vs. Mineral-Filled