16 Aug What Is an ACP Panel and How Is It Made

Table of Contents

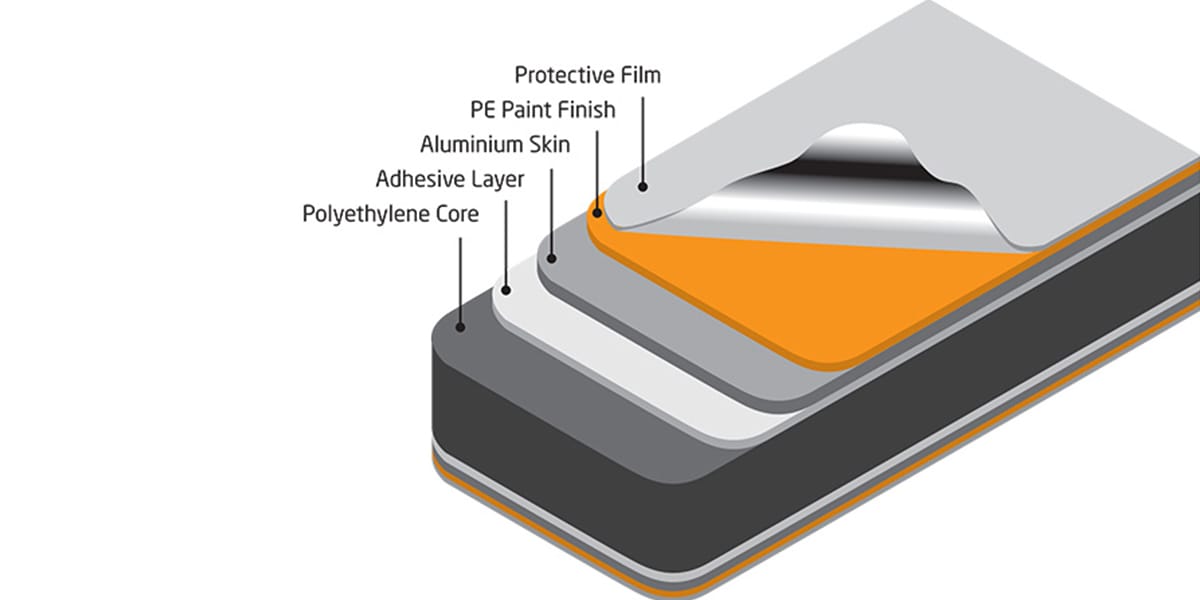

An acp panel, or aluminum composite panel, is a new building material. It is made by sticking two thin aluminum sheets to a strong plastic core. This three-layer design makes the panel strong, light, and bendable. Makers use aluminum and a core of polyethylene or a fire-safe material. This helps keep the panel safe and long-lasting. They join the aluminum layers to the core with heat and pressure. Knowing how an acp panel is made helps you pick the best material for your job. This is important because more people are using aluminum composite panels around the world.

Key Takeaways

ACP panels have three layers. Two are aluminum sheets. The middle layer is a strong core. This makes them light. They are also strong and can bend easily.

Fire-rated cores help keep people safe. They slow down fire. They also meet tough fire rules. This is very important for tall buildings.

Making ACP panels starts with cleaning the aluminum. The core is also prepared. The layers are stuck together with heat and pressure. Then, a protective finish is added.

ACP panels are simple to put in place. They can handle bad weather. They come in many colors and styles. You can use them inside or outside.

Picking the right core and finish is important. It helps the panels last longer. It keeps people safe. It also makes your building look good.

ACP Panel Structure

ACP Panel Materials

ACP Panel Materials

When you look at aluminium composite panels, you see more than a shiny look. These panels use different materials that work together. This gives you strength, safety, and style. The main parts are two thin aluminum plates and a core. The aluminum can have many finishes, like painted colors or wood grain. The core can be regular plastic or a fire-rated material for more safety.

Here is a table that shows the main materials and their properties:

Material Component | Description / Properties |

|---|---|

Aluminum Plates | Two aluminum plates bonded to a core; can have various finishes including pre-painted surfaces and wood grain patterns. |

Core Material | Modern panels use a fire-retardant (FR) core replacing the older polyurethane core due to fire safety concerns. |

Fire Safety Classification | Panels classified as A2 (non-combustible), B1 (fire-retardant), B2 (combustible traditional), B3 (flammable, not recommended). |

Physical Properties | Lightweight, durable, corrosion-resistant, energy-efficient, sound insulating, recyclable. |

Advanced Types | Nano aluminum composite panels offer enhanced water protection and longer lifespan. |

Application Suitability | Suitable for both exterior and interior architectural applications due to versatility and cost-effectiveness. |

These panels are light and easy to move. They are strong enough for many jobs. Aluminium composite panels do not rust and can handle bad weather. You can use them inside or outside buildings.

Three-Layer Design

The three-layer design makes aluminium composite panels special. There is a top aluminum sheet, a core, and a bottom aluminum sheet. Each layer has its own job.

The top aluminum sheet gives strength and protects from weather.

The core layer adds flexibility, insulation, and fire resistance.

The bottom aluminum sheet supports the panel and blocks sound.

This design keeps the panel light but tough. You can bend or shape it for many projects. The panel can handle impacts, rain, and fire. It also gives better sound and heat insulation. This helps keep buildings quiet and saves energy.

Tip: The three-layer structure lets you use aluminium composite panels for walls and ceilings. You can use them inside or outside. They are easy to cut and install.

Fire-Retardant Core

Safety is important when picking building materials. That is why many aluminium composite panels now have a fire-rated core. You can pick panels with a polyethylene core or a fire-retardant core. The fire-rated core uses minerals to slow flames and stop toxic smoke.

Here is a table that compares the two types of cores:

Aspect | Polyethylene (PE) Core Panels (ACP) | Fire-Retardant Core Panels (ACM) |

|---|---|---|

Core Material | Polyethylene (flammable) | Mineral-filled or fire-resistant core |

Fire Resistance | Lower; flammable, may release toxic gases | Higher; fire-retardant, meets stricter fire codes |

Weight | Lighter (~2.5 lbs/ft²), easier handling | Slightly heavier due to denser core |

Cost | Less expensive, suitable for budget projects | More expensive due to fire-resistant materials |

Application Scenarios | Best for interiors, low-rise buildings | Preferred for high-rise, high-risk buildings |

Sound Insulation | Moderate | Better sound insulation due to denser core |

Regulatory Compliance | May not meet strict fire safety codes | Meets stringent fire safety regulations |

If you need panels for tall buildings or places with strict fire rules, choose fire-rated aluminum composite panels. These panels do not burn easily and help keep people safe. They also block more noise and last longer in tough places.

Note: Always check the fire safety grade of your aluminium composite panel. Grades like B1 or A2 mean the panel is fire-retardant and safer for big projects.

ACP Panel Manufacturing

Manufacturing acp sheets involves several important steps. Each step helps you get panels that are strong, safe, and ready for many uses. You will see how raw materials turn into finished acp sheets with the right properties for your project.

Manufacturing acp sheets involves several important steps. Each step helps you get panels that are strong, safe, and ready for many uses. You will see how raw materials turn into finished acp sheets with the right properties for your project.

Aluminum Sheet Preparation

You start with high-quality aluminum coils. These coils must be clean and free from oil or dust. Workers clean and degrease the aluminum to remove any impurities. This step is important because it helps the coatings and adhesives stick better.

You can choose from different thicknesses and grades for your acp sheets. Here are some common options:

3mm acp sheets work well for both inside and outside projects.

4mm acp sheets give you more strength and flexibility, perfect for outside walls and complex shapes.

5mm acp sheets offer extra durability and soundproofing, great for building exteriors.

Fire-retardant grades like FR A2+ improve safety in acp panels.

The aluminum skin itself comes in several thicknesses, such as 0.1mm, 0.2mm, or even 0.5mm. You can also pick from different alloy grades, like 1100, 3003, or 5005, to match your needs. The right choice gives your acp sheets better weather resistance and longer life.

Common Values / Grades | |

|---|---|

Panel Thickness | 3mm, 4mm, 5mm, 6mm |

Aluminum Skin Thickness | 0.1mm, 0.12mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm |

Aluminum Alloy Grades | 1100, 3003, 5005 |

Core Fire Retardant Grades | FR B1, FR A2 |

Tip: Thicker acp sheets give you more strength and better impact resistance, especially for outside use.

Core Material Processing

The core of acp sheets is usually made from polyethylene (PE) or a fire-retardant mix. You start by preparing the raw materials. For fire-safe panels, you mix PE with special flame retardants and additives. Some factories use nano-level flame retardants to make the core even safer and stronger.

Here is how you process the core material:

Prepare and mix the raw materials.

Use machines to melt and blend the mix into small pellets.

Press these pellets into flat sheets for the core.

Treat the surface to help it bond well with the aluminum layers.

Test the core for strength, fire safety, and flexibility.

This process gives you a core that meets strict fire safety rules, like B1 grade. It also makes sure your acp sheets have good peel strength and do not crack at the edges.

Bonding and Lamination

Bonding is the heart of making acp sheets. You sandwich the core material between two aluminum sheets. Then, you apply a special adhesive to help them stick together. The next step uses heat and pressure to bond the layers into one solid panel.

The bonding process looks like this:

Lay out the aluminum sheets and the core.

Apply adhesive and primer coatings evenly.

Use high-pressure rollers and ovens to heat and press the layers together.

Cool the panels to room temperature.

The right heat and pressure are key. High temperatures help the adhesive flow and bond better. Pressure from rollers makes sure the layers stick evenly, so you do not get bubbles or weak spots. This method gives your acp sheets strong bonds, so they last longer and resist harsh weather.

Parameter | Effect on Bonding Strength and Durability |

|---|---|

Improves bonding by making the adhesive flow and stick better. Also helps the aluminum bond tightly to the core. | |

Increased Pressure | Makes the layers stick evenly. Too much pressure can cause warping, so you need the right balance. |

Hot Rolling | Lets you make panels of different thicknesses with strong bonds. |

Note: Uniform bonding is important. If you do not use the right heat and pressure, your acp sheets may peel or break over time.

ACP Sheets Fabrication

After bonding, you finish the acp sheets with several steps. You cut the panels to the right size and trim the edges. Some panels get extra surface treatments, like special finishes or coatings. These finishes can be glossy, matte, wood grain, or even nano-coatings for better scratch and UV resistance.

After bonding, you finish the acp sheets with several steps. You cut the panels to the right size and trim the edges. Some panels get extra surface treatments, like special finishes or coatings. These finishes can be glossy, matte, wood grain, or even nano-coatings for better scratch and UV resistance.

Here are the main fabrication techniques:

Apply coatings like PE, PVDF, or nano finishes to protect against weather, fire, and dirt.

Cold roll the aluminum sheets to make them flexible and strong.

Assemble multi-layered panels with fire-retardant or honeycomb cores for added safety.

You also need to check the quality of your acp sheets. Factories test for peel strength, bending, fire resistance, and weather durability. They use tests like chemical analysis, hardness checks, and peel-off strength tests. These tests make sure your acp sheets meet international standards, such as ASTM, UL, RoHS, and REACH.

Test Name | Description |

|---|---|

Chemical Composition Analysis | Checks the aluminum for the right mix of metals. |

Hardness Test | Measures how tough the aluminum is. |

Makes sure the layers do not come apart. | |

Flexural Strength & Modulus | Tests how much the panel can bend without breaking. |

Normal Weather Test | Checks if the panel lasts in sun, rain, and wind. |

Calorific Value Test | Measures how well the core resists fire. |

Alert: Always look for acp sheets that pass strict quality tests. This ensures safety and long life for your building.

Modern acp sheets also use new technology. Some use recycled materials or eco-friendly finishes to lower their impact on the environment. Nano-coatings make the panels last longer and resist scratches. These innovations help you get acp sheets that are safer, greener, and easier to maintain.

Tip: Choose acp sheets with the right finishes and thickness for your project. This gives you better looks, safety, and performance.

Types and Features of Aluminium Composite Panels

Main Types of Aluminium Composite Panels

Main Types of Aluminium Composite Panels

There are many kinds of aluminium composite panels you can buy. These panels have different looks and finishes for your design. Some common types are:

Coating Decorative Panels: These use polyester or acrylic coatings. You can pick metallic, plain, or pearl finishes. They are good for indoor spaces.

Oxidized Color Panels: These use anodized aluminum. You get colors like rose red or bronze with shiny effects.

Laminated Decorative Panels: These have color films with wood grain, abstract, or flower designs.

Brushed Panels: These look like brushed silk, often in gold or silver.

Mirror Panels: These look like mirrors because of their shiny surface.

You can also sort aluminium composite panels by how you use them. Some are for wall cladding, some for outdoor signs, and some for inside decoration. There are special panels too, like fireproof, antibacterial, and anti-static types. This big variety makes aluminium composite panels useful for many jobs.

Key Features and Benefits

Aluminium composite panels have many good features and benefits. They are light, so you can carry and install them easily. These panels last a long time, even in bad weather. They do not rust, and they resist water and UV rays. You can choose from many colors, textures, and finishes. This helps you make your building look just right.

Features of Aluminium Composite Panel | Advantages |

|---|---|

Lightweight and easy to install | Saves time and labor costs |

High durability | Lasts 20-50 years with little maintenance |

Versatile design options | Fits many applications, both inside and outside |

Fire and water resistance | Safe for homes and offices |

Low maintenance | Needs only simple cleaning |

Tip: The advantages of aluminium composite panel are cost savings, design choices, and long-lasting use. You can use them for walls, ceilings, signs, and more.

Comparison with Other Materials

When you look at aluminium composite panels next to other materials, you see clear benefits. These panels are lighter than stone or solid aluminum, so you can put them up faster. They keep heat in better than solid aluminum, which saves energy. You also spend less money on care over time.

Material | Weight | Durability | Installation | Maintenance | Cost |

|---|---|---|---|---|---|

Aluminium Composite Panels | Lightweight | High | Easy | Low | Moderate |

Solid Aluminum | Heavy | High | Hard | Low | High |

Wood | Light | Low | Moderate | High | Moderate |

Stone | Heavy | High | Hard | Low | High |

Concrete | Heavy | High | Hard | Low | Moderate |

You get the advantages of aluminium composite panels like lower costs, easy setup, and many uses. Their features make them a smart pick for new buildings.

Applications and Installation

Uses of Aluminium Composite Panel

Aluminium composite panels are used in many places. They are strong and light. You can shape them easily. These panels work for inside and outside jobs. Here are some ways people use them:

They cover the outside of buildings like offices and hotels. The panels protect and make buildings look modern.

People use them to decorate inside walls and ceilings. You can pick from many colors and styles.

They are good for signs and billboards. The panels stay flat and bright, even in bad weather.

You can use them for furniture like cabinets and wardrobes. Panels with wood or stone looks are stylish and last long.

They are also used in buses, vending machines, and equipment covers. The panels do not rust and are safe.

You can see that the uses of aluminium composite panel are in many fields. These panels help you build safe and nice-looking things that last.

How to Install Aluminium Composite Panel

Learning how to install aluminium composite panel is important. It helps your project stay strong and look good. The most common way is called the cassette system. First, you build a metal frame on the wall. Then, you cut and fold the panels into trays. You drill holes and attach the panels with screws or rivets. Always leave a small gap between panels so they can expand.

Use sealants to keep water out and make seams neat.

Add trim to protect the edges of the panels.

Leave space behind the panels for air to move. This stops heat and moisture from building up.

Put in drainage to guide water away from the wall.

Use joints and flexible fasteners to stop buckling.

Tip: Always check the panel direction when you install. This keeps the color and finish looking the same.

Check your panels often and keep them clean. Good installation stops leaks and loose panels. It also keeps the color from fading. These steps make aluminium composite panels a smart pick for many uses.

Safety and Fire Resistance

Safety matters a lot with aluminium composite panels. Some old panels had flammable cores. These made fires spread fast. Now, you can pick panels with fire-resistant cores. These slow down fire and meet strict rules.

Standard / Code | Purpose / Focus | Applicability / Requirements |

|---|---|---|

Checks flame and smoke spread | Used for aluminium composite panels in buildings | |

NFPA 285 | Tests fire on outside walls | Needed for tall buildings with wall panels |

ASTM E119 | Checks fire resistance of building parts | Used for cladding systems |

IBC | Needs fire-rated panels and rules above | Needed for safe use in tall buildings |

Always choose panels that meet these standards. Fires like the Grenfell Tower showed the danger of flammable panels. Fire-rated panels help keep people and buildings safe. They stop fire from spreading. Always follow fire safety rules for every job.

Alert: Never use panels without fire ratings in tall buildings. Always check local rules and pick panels with the right fire rating for your job.

You have learned that an acp panel uses two aluminum sheets and a strong core. This makes the panel light and tough. It is a good choice for building things. The table below shows the main benefits and where you can use these panels:

Aspect | Details |

|---|---|

Advantages | Light but strong, stands up to weather, fire-safe, looks nice, easy to clean, saves energy, can be recycled |

Typical Applications | Tall buildings, houses, outside walls, signs, inside spaces, furniture, vehicles |

You can pick acp panels because they are simple to put in, last a long time, and come in many styles.

These panels help you make safe, new, and budget-friendly places.

Tip: Pick the best core and finish for your job to get the best outcome.

FAQ

What is an ACP panel used for?

You can use an ACP panel for lots of things. People put them on outside walls and building fronts. They are also good for signs and inside decoration. ACP panels are light and easy to work with. You can use them in homes, offices, and stores.

How do you install aluminium composite panels?

First, measure and cut the ACP sheets to fit. Next, attach them to a frame using screws or rivets. Always leave a little space so the panels can expand. Use sealants and trims to make the edges look neat. This way works for both inside and outside jobs.

What are the main features of aluminium composite panel?

ACP panels have many good features. They are light, strong, and can handle bad weather. You can pick from many colors and finishes. Some panels are fire-rated for more safety. They are easy to clean and keep looking new for a long time.

Are aluminium composite panels fire-safe?

Many ACP panels now have a fire-rated core. This makes them safer if there is a fire. Always check the fire rating before you buy any panels. Fire-rated ACP panels help keep buildings and people safe during a fire.

ACP Panel Materials

ACP Panel Materials Main Types of Aluminium Composite Panels

Main Types of Aluminium Composite Panels