06 Dec A Buyer’s Guide To Aluminum Sandwich Panels

Table of Contents

- 1 Key Takeaways

- 2 Aluminium Sandwich Panel Guide: What You Need to Know

- 3 Key Benefits of Sandwich Panels

- 4 Types of Sandwich Panels and Their Applications

- 5 How to Choose the Best Sandwich Panel

- 6 Comparing Aluminium Composite Panels to Alternatives

- 7 Installation and Maintenance Tips

- 8 Sustainability and Environmental Impact

- 9 FAQ

When you pick an aluminum sandwich panel in 2025, you have many big questions. Fire safety is very important. Durability matters a lot too. Eco-friendly features are also important now. Market data shows the market is growing fast. The aluminum sandwich panels market will reach $18.3 billion in 2025, growing at a 7.7% rate. Buyers want energy efficiency. They want panels that are easy to install. They also want materials that are good for the planet. Many projects use these panels in prefabricated buildings and modern designs. Use this aluminium sandwich panel guide to help you make smart, safe, and future-ready choices.

Key Takeaways

Pick aluminum sandwich panels because they are safe from fire and last long. Check if the panels have safety certificates like UL 263 and ASTM E119. These certificates help make sure the panels are safe.

Think about saving energy when you choose panels. Good insulation can help you save up to 20% on your energy bills. It also lowers heating and cooling costs a lot.

Choose the core type that fits what you need. You can pick polyurethane or mineral wool cores. Each type gives different benefits, like better insulation or more fire safety.

Look for panels that are good for the environment. Aluminum sandwich panels can be recycled. They help lower your carbon footprint. This makes them a smart choice for the planet.

Buy from trusted suppliers. Make sure they give you good materials and safety certificates. They should also offer good support after you buy to keep your investment safe.

Aluminium Sandwich Panel Guide: What You Need to Know

Panel Structure and Core Design

Every aluminium sandwich panel has three main parts. The outside layers are called skins. These skins use aluminum to make the panel strong. The middle part is the core. The core helps keep heat in or out. This design makes the panels strong and light. It also helps save energy.

The skins make the panel tough and protect it.

The core keeps rooms warm or cool.

The core also helps stop noise, so rooms are quieter.

There are different core shapes in these panels. The shape of the core changes how the panel works. An X-frame core can take in more energy. It spreads out stress better. This helps the panel last longer and hold more weight. An H-frame core does not spread stress as well. It might break sooner.

Core Geometry | Energy Absorption | Damage Area | Performance Characteristics |

|---|---|---|---|

X-frame | Superior | Smallest | Moves weight well and lowers stress |

H-frame | Limited | Largest | Not as strong, breaks faster |

Bonding Techniques and Material Selection

The layers in a panel must stick together well. Good bonding keeps the panel safe and strong. Epoxy adhesives are very strong and last a long time. They work even in hard places. Polyurethane adhesives are good if the panel needs to bend or shake.

Epoxy adhesives fight bad weather and keep panels strong.

Polyurethane adhesives bend and handle hot or cold days.

Picking the right materials is important. The outside layers can be pre-painted aluminum or galvanized sheets. These last longer and fight bad weather. The core can be honeycomb shaped. This makes the panel strong but not heavy. Polyurethane foam cores help save energy by keeping heat in or out. Mineral wool cores stop fire and block noise. These are good for factories or offices.

Material Type | Benefits |

|---|---|

Outer Aluminum Layers | Pre-painted and galvanized, last long and fight bad weather |

Honeycomb Cores | Strong and light, easy to move |

Polyurethane Foam Cores | Save energy by keeping heat in or out |

Mineral Wool Cores | Stop fire and noise, good for safety and comfort |

Using this aluminium sandwich panel guide helps you pick the best panels. You get panels that last, save energy, and keep people safe.

Key Benefits of Sandwich Panels

Insulation and Fire Safety

Insulation and Fire Safety

You want your building to be safe and comfy. Sandwich panels help with both things. The core inside stops heat and cold. Rooms stay warm in winter and cool in summer. These panels also protect against fire. They have strong safety features. Many panels meet top fire safety rules. Here are some certifications you should know:

Description | |

|---|---|

ASTM E119 | Fire test for building materials and assemblies. |

EN 13501-2 | European standard for fire classification of construction products. |

UL 263 | Standard for fire tests of building construction and materials. |

The NFPA 285 rule checks how fire moves in walls with aluminum composite materials. Some panels, like ALUCOBOND PLUS, meet NFPA 285. This means they give strong fire protection and safety.

Durability and Lightweight

Sandwich panels last for many years. You can count on them for 40 to 50 years if you care for them. These panels fight bad weather, rust, and sun damage. You do not need to worry about rust or the sun hurting them. Sandwich panels weigh less than wood or steel. You can move and put them in place easily. Their light weight helps lower building costs. It also makes building faster. You get a strong material that does not break down fast.

Tip: Pick sandwich panels for jobs where you need strength and easy moving.

Eco-Friendly Features

You help the earth when you use sandwich panels. These panels can be recycled, so you do not make extra trash. They save energy by keeping heat in or out. This lowers your bills and cuts down carbon emissions. You need less upkeep, so you spend less money over time. Sandwich panels let you make cool building designs. You can put them in quickly, which saves work and time.

Eco-Friendly Feature | Contribution to Sustainable Construction |

|---|---|

100% recyclable | Reduces waste and minimizes environmental impact of construction projects. |

Energy efficiency | Lowers energy costs and reduces overall energy consumption and carbon emissions. |

Durability | Requires less maintenance, making it cost-effective and long-lasting. |

Design versatility | Offers flexibility for unique designs, promoting innovative and sustainable architecture. |

Easy installation | Reduces labor costs and promotes efficient construction processes. |

You see the good things about sandwich panels in every part of your project. You get fire safety, strength, and eco-friendly features all together.

Types of Sandwich Panels and Their Applications

Aluminium Composite Panels

Aluminium composite panels are used in many new buildings. These panels have two thin aluminum sheets. There is a solid plastic core between them. The surface looks smooth and neat. You can use these panels for walls, signs, and ceilings. There are many colors and finishes to pick from.

Here is a table that shows how aluminium composite panels compare to another type:

Property | Aluminum Honeycomb Panel | Aluminum Composite Panel |

|---|---|---|

Core Material | Hexagonal aluminum honeycomb | Solid plastic core |

Weight | Very lightweight | Heavier than honeycomb |

Load-Bearing Capacity | High strength-to-weight ratio | Good for flat surfaces |

Shape Adaptability | Works for complex shapes | Best for flat or simple curves |

Surface Quality | Needs extra cladding | Smooth and ready to use |

Applications | Curved facades, heavy loads | Wall cladding, signage, ceilings |

Installation & Cost | Higher cost, easy to install | Lower cost, easy to install |

Aluminium composite panels are a cheap way to cover big spaces. They are easy to put in and look modern.

Other Panel Types

You can choose from different sandwich panels for your project. Each type has its own core material:

Polystyrene (EPS): Good for walls that do not hold much weight. It keeps rooms warm or cool.

Polyurethane (PUR): Best for cold places and storage. It keeps temperatures steady.

Mineral Wool: Great for stopping fires. Use these where fire safety matters most.

These sandwich panels help you make buildings safer and save energy.

Uses in Prefabricated Buildings and Modern Construction

Sandwich panels are found in many types of buildings. They work in factories, stores, and homes. You can use them for walls, roofs, and building covers. Prefabricated buildings use sandwich panels because they are light. You can move them easily and install them fast. This saves time and money.

Tip: Sandwich panels help you build faster and spend less on workers.

Sandwich panels keep buildings warm or cool. They help lower energy bills. Their light weight makes moving and installing easy. Many builders pick sandwich panels because they cost less and work better than old materials.

How to Choose the Best Sandwich Panel

When you pick a sandwich panel in 2025, you need to think about a few big things. You want your building to be safe, strong, and look nice. This guide shows you how to pick the right sandwich panel by breaking the steps into easy parts.

When you pick a sandwich panel in 2025, you need to think about a few big things. You want your building to be safe, strong, and look nice. This guide shows you how to pick the right sandwich panel by breaking the steps into easy parts.

Fire Safety and Certifications

Safety is the most important thing when picking sandwich panels. You must check if the panels follow fire safety rules. These rules help keep people and buildings safe from fire. Always pick panels that pass tests from trusted groups. Here are some main fire safety certifications you should know:

Standard | Description |

|---|---|

UL 263 | Sets fire resistance rules for building materials. |

ASTM E119 | Gives ways to test fire resistance. |

NFPA 285 | Checks fire safety for outside wall systems. |

You should also look for certifications from groups like ANSI or ASTM. These show the panels meet safety rules for the industry. Ask your supplier about their quality checks. Good suppliers test their panels often and check materials before making them. This helps keep every project safe.

Tip: Always ask for test reports and certificates before you buy. This keeps your project safe and follows the rules.

Thickness and Core Types

The thickness and core type of sandwich panels change how safe and strong they are. Thicker panels give better insulation and more safety. The core inside the panel changes how it handles shocks, heat, and fire.

Panels with low-middle-high density cores handle shocks better.

More core layers mean better blast resistance and higher safety.

Graded cores help the panel handle different loads and keep people safe.

You should match the panel thickness and core type to your building’s needs. For example, use thicker panels with mineral wool cores where fire safety is very important. Polyurethane cores are good for cold storage because they keep temperatures steady. Always think about safety and the good points of each core type before you choose.

Finishes and Supplier Recommendations

The finish on sandwich panels changes how your building looks and how long the panels last. You can pick from many finishes, and each one has its own good points for safety and style.

Finish Type | Description | Effects on Durability and Aesthetics |

|---|---|---|

Polished | Smooth, shiny surface | Good for fancy decoration. |

Brushed | Fine lines on the surface | Looks nice and hides scratches. |

Mirror | Very shiny surface | Made by careful polishing. |

Anodized | Hard outer layer | Stops rust and makes it last longer. |

Coated (PVDF/PE) | Many colors to pick | Fits many design needs. |

Embossed | Patterns pressed in | Stops slipping and looks cool. |

When picking acm panels, you should also check the supplier’s reputation. Good suppliers give you strong materials, new ways to make panels, and help after you buy. Here are some things to look for:

Criteria | Description |

|---|---|

Material Quality | Good core and face materials last longer and work better. |

Manufacturing Capabilities | New machines let them make many kinds of panels. |

Design Flexibility | They can make panels in many sizes, shapes, and finishes. |

Cost Efficiency | Good prices without losing quality help you save money. |

Certification & Compliance | Certifications like ISO, CE, and ASTM show the panels are safe and good. |

Delivery & Lead Time | Fast shipping and quick work help your project stay on time. |

After-Sales Support | Help, warranties, and training make your panels last longer. |

Innovation & R&D | Companies that invent new things make better, lighter, and stronger panels. |

Pick suppliers with strong quality checks.

Make sure they test their products and materials often.

Choose companies that give help and warranties.

Note: Good suppliers help you get the best panels and keep your project safe.

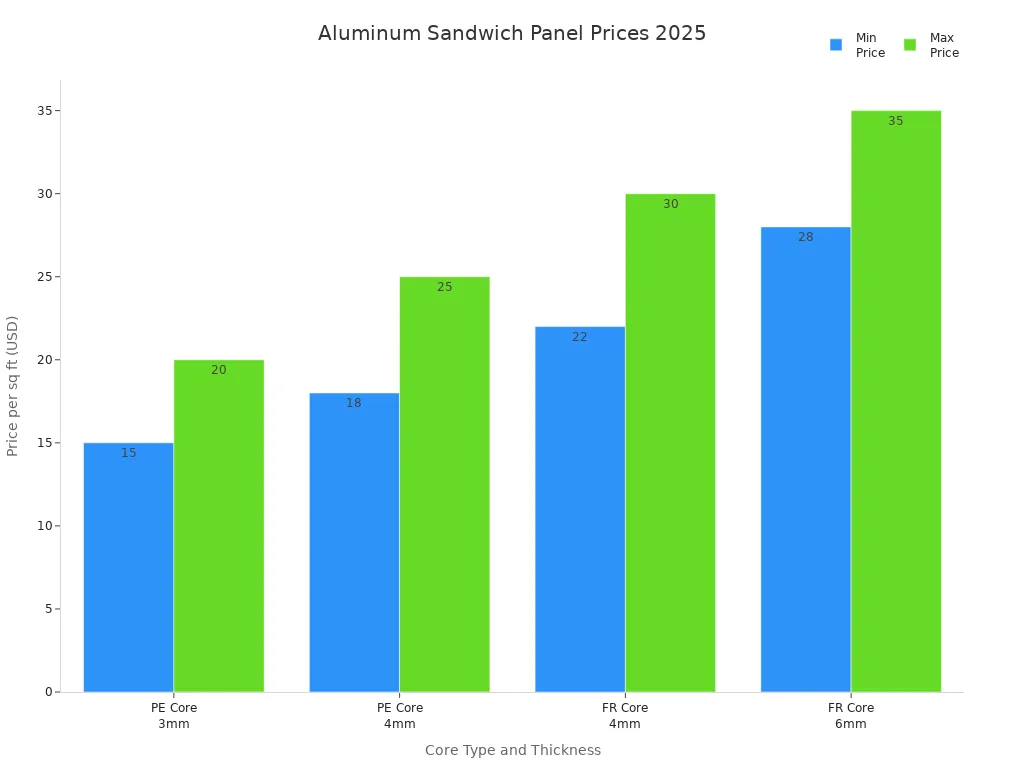

Pricing and Specifications

Knowing the price and details of sandwich panels helps you make smart choices. Prices change based on the core type, thickness, and extra features. Here is a table showing usual prices in 2025:

Core Type | Thickness | Price Range (per sq ft) |

|---|---|---|

PE Core | 3mm | $15 – $20 |

PE Core | 4mm | $18 – $25 |

FR Core | 4mm | $22 – $30 |

FR Core | 6mm | $28 – $35 |

Other things that change the price are:

Core type and thickness

Labor costs in your area

How hard it is to install

Extra work like sealing or painting

Local market prices

Special cuts or shapes

Picking acm panels can save you money on putting them in. These panels are lighter than steel, so you need fewer workers and less support. You can save up to 30% on installation costs compared to steel panels.

When you look at technical details, focus on these things:

Specification Type | Description |

|---|---|

Core Material | The core material changes how strong, safe, and warm the panel is. |

Adhesive/Bonding | Strong glue keeps the panel together for a long time. |

Density | Makes sure the building can hold the panel’s weight. |

Fire Ratings | Shows how the panel burns and makes smoke; rules change by place. |

Thermal Conductivity (λ) | Lower λ means the panel keeps heat in or out better. |

Thermal Transmittance (U) | Lower U means the panel is better at stopping heat from moving. |

Sound Insulation | Higher dB means the panel blocks more noise. |

Water Vapor Permeability | Shows how well the panel keeps water out. |

Mechanical Resistance | Important for panels that face wind or snow. |

Check the core material for safety and warmth.

Make sure the glue is strong and lasts.

Look at fire ratings and insulation for safety and comfort.

Check sound and water resistance for better building quality.

Tip: Always compare details and prices from different suppliers. This helps you find the best sandwich panel for your needs and keeps your project safe.

By following these steps, you get safety, strength, and style. You also make sure your building follows all rules and lasts a long time. When you know how to pick the best sandwich panel, you protect your money and make a safer place for everyone.

Comparing Aluminium Composite Panels to Alternatives

Aluminium vs. Steel Panels

You might wonder how aluminum composite panels and steel panels are different. Both types are strong, but they are not the same. Aluminum composite panels are much lighter than steel panels. This makes them easier to carry and put in place. Steel panels are heavier, but they are stiffer and stronger if they are the same thickness. Steel panels can cost a bit more, especially if you want extra strength. Here is a table that shows the main ways they are different:

Attribute | Aluminum Composite Panels (ACM) | Steel Composite Panels (SCM) |

|---|---|---|

Weight | Lightweight | Heavier |

Strength/Stiffness | Good, but less than steel | Higher rigidity |

Cost | Competitive | Slightly higher |

Tip: Pick aluminum composite panels if you want to save money and weight. Choose steel panels if you need more strength and toughness.

Composite vs. Traditional Materials

You can also look at how composite sandwich panels compare to old building materials like concrete or brick. Composite panels keep heat in during winter and out during summer. This means your building stays comfortable all year. You can put these panels up quickly, which saves time and money. Old materials take longer to build with and often need more insulation. Here is a table to help you see the differences:

Feature | Composite Sandwich Panels | Traditional Materials (Concrete/Brick) |

|---|---|---|

Energy Efficiency | Moderate insulation | |

Installation Speed | Fast | Slow |

Cost-Effectiveness | Lower costs | Higher costs |

Durability | Strong outer layers | Durable, but can crack |

Note: Composite panels help you finish your building faster and use less energy.

Pros and Cons Overview

It is good to know the main good and bad points before you pick a panel. Aluminum composite panels last a long time and do not need much care. They stand up to bad weather and fire. You can use them in many ways, and they often cost less than other choices. But they can get dents if something hits them hard. Rain or hail can make noise on the panels. You have to seal them well to stop water from getting in.

Advantages | Disadvantages |

|---|---|

Durability | Denting |

Low maintenance | Noise from rain or hail |

Weather resistance | Insulation challenges |

Fire resistance | Need careful sealing |

Design flexibility |

|

Cost efficiency |

|

Light metal panels work in many places.

They stand up to tough weather and rust.

You can put them in fast.

They might get bigger or smaller when it is hot or cold, so check for leaks.

Remember: Think about what your project needs before you pick a panel. The right panel helps you save time, money, and work.

Installation and Maintenance Tips

Preparation and Best Practices

Preparation and Best Practices

You want your aluminum sandwich panels to work well and last long. Getting ready the right way is very important. First, read all the design papers before you start. Make sure you have every tool and material you need. You can put the panels up straight or sideways. Each way has its own steps to keep the building strong. Always seal the joints with the right stuff. This keeps water out and helps with heat and sound.

Here are some tips for putting in panels:

Check if the base is strong and flat before starting.

Keep panels flat and inside so they do not get hurt.

Use waterproof paint to keep water away from the panels.

Leave space for the panels to grow or shrink, as the maker says.

Tip: Plan well and install the right way to save energy and keep your building safe.

Common Mistakes to Avoid

Many building jobs have problems because of easy mistakes. You can stop these problems by following good steps. The table below shows mistakes and how to fix them:

Solutions | |

|---|---|

Incorrect Panel Orientation | Look at the arrows on the film. Make sure all panels face the same way. |

Ignoring Thermal Expansion Requirements | Leave space for panels to move. Do not make them too tight. |

Using the Wrong Sealant or No Sealant | Use special silicone sealants. Do not use cheap ones. |

Improper Joint Widths | Use the right joint size. Make sure joints are even. |

Incorrect Rivet or Fastener Selection | Pick fasteners that do not rust. Match colors if you want. |

Overtightening the Fasteners | Do not make fasteners too tight. Let panels move a little. |

Removing the Protective Film Too Early | Keep the film on until you finish most of the work. |

Improper Storage Before Installation | Store panels flat and inside. Protect the edges from getting hurt. |

Cutting Panels Incorrectly | Use the right saws for aluminum. Do not use bad cutting tools. |

Skipping the Substructure Inspection | Always check the base for strength and rust. |

Note: If you avoid these mistakes, your panels will go in better and last longer.

Cleaning and Longevity

You want your panels to look nice and last many years. Clean and check them often. Use soft soap and a soft cloth to clean the panels. Do not use rough tools that can scratch them. Check the joints and edges for water or rust. Watch for paint coming off and fix it fast. Pick panels with PVDF or FEVE coatings to stop fading and weather damage.

Here are some easy ways to care for your panels:

Clean panels often to get rid of dust and dirt.

Fix any loose or broken parts right away.

Use fire-rated panels for tall buildings to stay safe.

Make sure panels stay flat and tight after you put them in.

Tip: Good care and cleaning help your panels save energy and keep your building looking new.

Sustainability and Environmental Impact

Recyclability and Green Standards

When you pick aluminum sandwich panels for outside walls, you help the planet. These panels can be recycled many times. Both the aluminum skins and the core can be reused. Many places, like China, now ask for green building rules. These panels are used in buildings that save energy. They help builders follow strict rules.

Evidence Description | Recyclability | Green Building Standards |

|---|---|---|

Aluminum composite panels are easy to recycle and used in green buildings. | High | LEED and other certifications in growing markets like China. |

China’s new building rules say to use recyclable materials and follow LEED and Three-Star System. | High | LEED and Three-Star System. |

Aluminum honeycomb panels are recyclable and help save energy in buildings. | High | Eco-friendly choice. |

Tip: Pick panels with LEED or Three-Star System labels for outside walls. These labels show your building is good for the environment.

Reducing Carbon Footprint

You can help lower pollution by making smart choices when building. Using recycled aluminum and bio-based polyethylene cuts carbon by more than 77%. Recycling waste and saving energy in factories also helps the earth.

Use recycled aluminum in your panels.

Pick bio-based materials for the core.

Recycle leftover materials from making panels.

Use machines that save energy in factories.

Teach workers to use less energy.

PU sandwich panels with high efficiency also cut carbon. Their making process releases only 60% of the carbon compared to old EPS foam. You help the earth and save money over time.

Energy Efficiency

Aluminum sandwich panels help buildings use less energy. Special core materials like polyurethane and polystyrene keep heat inside in winter and outside in summer. This means you do not need as much heating or cooling.

You can save up to 20% on energy bills.

Good cores can lower heating and cooling costs by 60%-70%.

The panels stop thermal bridges, which are weak spots in insulation.

Seamless panels and steady insulation make buildings work better.

You see these panels on many outside walls because they keep buildings comfy and use less energy. Their strong insulation helps the planet and makes them a smart pick for new buildings.

When picking aluminum sandwich panels in 2025, think about the most important things. Fire safety and how long the panels last are key. Energy efficiency is a big deal and shapes a lot of the market. Light panels are easier to move and use. Eco-friendly features help the planet and follow new rules. Good suppliers have strong safety certificates.

You should do these steps:

Decide what your project needs and what you want to achieve.

Look at different suppliers to see who has better quality and more choices.

Make sure the panels have the right safety certificates.

Ask for samples before you make your choice.

Next, learn more or talk to trusted suppliers to get samples and prices.

FAQ

What is the main advantage of aluminum sandwich panels?

You get strong panels that weigh less than steel or concrete. These panels save energy and last a long time. You can install them quickly. They also help keep your building safe from fire.

How do I know if a panel is fire safe?

Check for fire safety certificates like UL 263, ASTM E119, or NFPA 285. Ask your supplier for test reports. Always choose panels that meet local building codes.

Can I recycle aluminum sandwich panels?

Yes! You can recycle both the aluminum skins and many core materials. This helps reduce waste and supports green building standards.

How do I clean and maintain these panels?

Use mild soap and a soft cloth. Avoid harsh chemicals or rough tools. Check joints and edges for damage. Clean panels regularly to keep them looking new.

Where can I use aluminum sandwich panels?

You can use them for walls, roofs, ceilings, and facades. Many builders use them in homes, offices, factories, and stores. They work well in prefabricated buildings.

Insulation and Fire Safety

Insulation and Fire Safety Preparation and Best Practices

Preparation and Best Practices