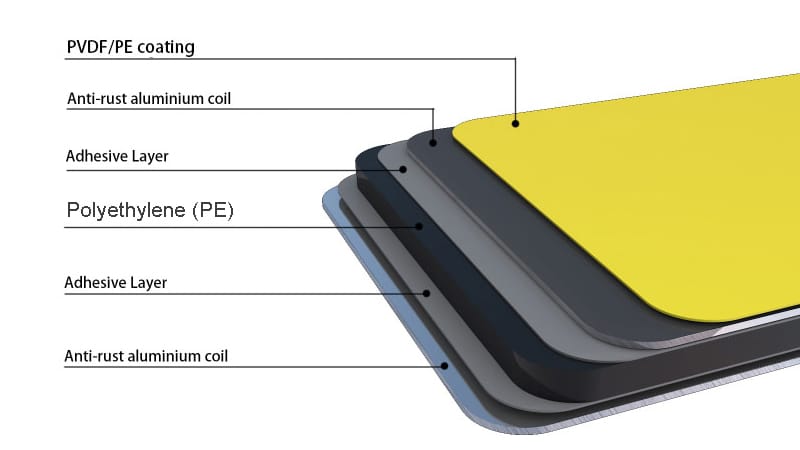

Facade aluminium composite panel (facade ACP), which stands for Aluminum Composite Panel, is a building material for exterior and interior finishes consisting of two thin aluminum sheets bonded to a core, typically made of polyethylene. These panels are popular for facades because they are lightweight, durable, easy to install, and provide a modern, aesthetically pleasing appearance with a variety of colors and finishes

Facade Aluminum Composite Panel Structure

- Protection Film

- PVDF Coating

- Aluminium Skin

- Adhesive Layer (Polyolefin)

- Polyethylene Core (PE)

- Adhesive Layer (Polyolefin)

- Aluminium Skin

- Service Coating (Anti-corrosive)

Key Benefits Of Facade ACP Sheet

Lightweight

Despite their strength, ACP sheets are lightweight, which reduces the load on structural elements and simplifies installation.

Durability

The composite structure of ACP provides durability that exceeds traditional materials, making it resistant to wear and tear, corrosion, and abrasion.

Weather Resistance

ACP sheets are designed to withstand harsh weather conditions, including rain, sun, and temperature fluctuations, without compromising their appearance or structural integrity.

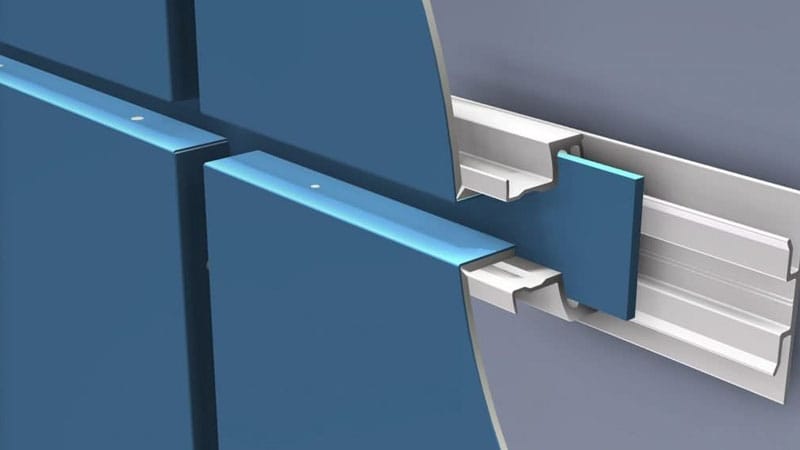

Easy To Install

The sheets are designed to be easily mounted on various surfaces, and their light weight reduces the need for additional structural support.

Design flexibility

Available in a wide variety of colors, textures, and finishes, they can be easily cut, folded, and shaped to meet specific design requirements.

Low Maintenance

The surface is easy to clean with water and mild soap, and the panels are designed to maintain their appearance for years with minimal upkeep.

Cost-Effective

They are economical due to their lower initial cost compared to some other materials, long lifespan, and reduced maintenance expenses.

Fire Resistance Option

Many panels are manufactured with a fire-retardant core, and they do not emit harmful fumes when exposed to fire.

Eco-friendly

They are recyclable and can be a sustainable choice, often incorporating recycled materials in their production.

Customization Service from ALCADEX

At ALCADEX, we offer tailored facade ACP sheet solutions to meet your requirements across various application scenarios, covering customizations of size, color, and texture finish.

Our color lab is capable of precisely reproducing any shade from RAL or PANTONE color charts, or developing exclusive finishes based on physical samples.

Leveraging advanced PVDF 70/30 coating technology, we ensure consistent coating and superior adhesion. This endows the panels with excellent anti-aging capabilities, exceptional UV resistance, and long-term durability during processing and forming.

Questions? We are happy to help

Contact us to get the latest quotes or customized solutions for your new projects