A2 fire-rated composite panels are building materials with limited combustibility, meaning they have a very low contribution to fire. They are composed of a non-combustible mineral-filled core, often made of materials like aluminum hydroxide and magnesium hydroxide, sandwiched between two aluminum sheets.

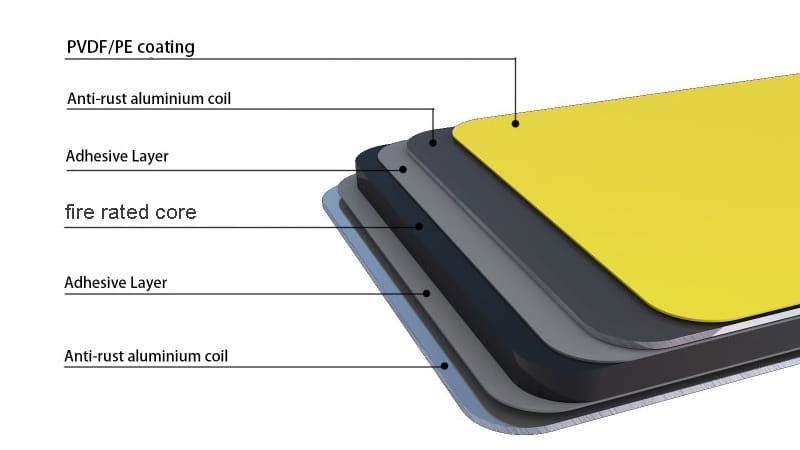

A2 Fire Rated Acp Sheets Structure

- Protection Film

- PVDF/Polyester Coating

- Aluminium Skin

- Adhesive Layer (Polyolefin)

- Fire Rated Core (mineral-filled)

- Adhesive Layer (Polyolefin)

- Aluminium Skin

- Service Coating (Anti-corrosive)

Key Characteristics Of A2 Fire-Rated Composite Panels

Fire performance

They are classified as A2-s1,d0, indicating a high level of fire resistance. While not entirely non-combustible like A1 materials, they are significantly less combustible.

Composition

The core is a non-combustible inorganic material, typically mineral-filled. Some versions use a 100% aluminum core for even higher fire resistance, as discussed on acmmanufacturer.com.

Fire behavior

When exposed to flames, these panels will not produce excessive heat or flaming droplets, and they are unlikely to melt. They are designed not to spread fire or produce toxic gases that would hinder escape routes.

Applications

A2 panels are recommended for facades, interior and exterior walls, ceilings, and tunnel linings, especially in public buildings, hospitals, and other locations with strict fire safety codes.

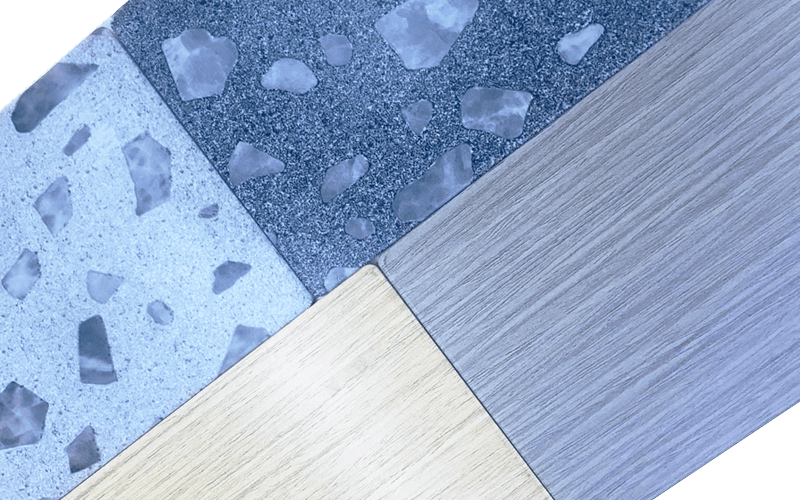

Customization Service from ALCADEX

At ALCADEX, we provide customized fire-rated ACP Panel services based on your needs for different application scenarios, including customizations of size, color, and texture finish.

Our color laboratory can accurately replicate any color from the RAL or PANTONE color charts, or create exclusive finishes according to physical samples.

With advanced PVDF 70/30 coating technology, we ensure uniform coating and excellent adhesion. This guarantees the panels have outstanding anti-aging properties, excellent UV protection performance, and long-lasting durability during processing and forming.

Questions? We are happy to help

Contact us to get the latest quotes or customized solutions for your new projects