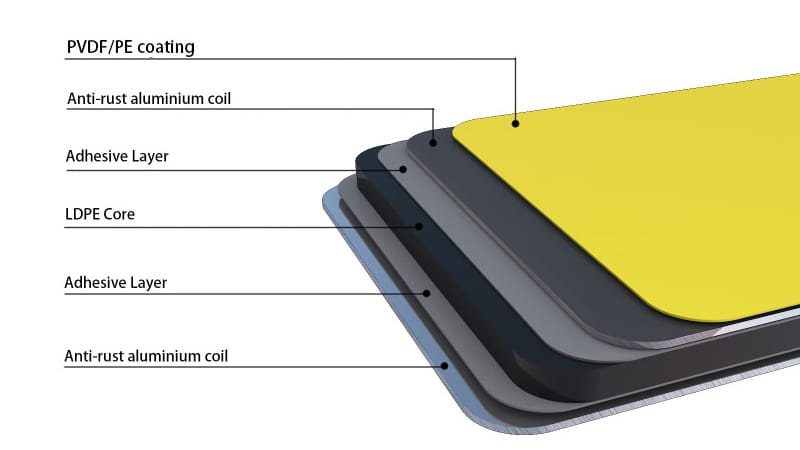

PVDF Aluminum Composite Panel, commonly referred to as ACP PVDF, is a lightweight, durable, and multi-functional building material. It is composed of two thin aluminum sheets bonded to a non-aluminum core, usually polyethylene or a mineral-filled substance, with the front aluminum sheet finished with a PVDF (polyvinylidene fluoride) resin coating.

PVDF coating, or Polyvinylidene Fluoride coating, is a high-performance liquid resin-based coating applied to metal, especially for architectural use, to protect it from weathering and fading

ACP PVDF Coating Panel Structure

- Protection Film

- PVDF Coating

- Aluminium Skin

- Adhesive Layer (Polyolefin)

- Polyethylene Core (LDPE)

- Adhesive Layer (Polyolefin)

- Aluminium Skin

- Service Coating (Anti-corrosive)

PVDF ACP Sheet Main Applications

PVDF coatings ACP Panel are highly resistant to chalking, fading, corrosion, and UV radiation, making them ideal for harsh weather and strong sunlight. It is widely used in various fields.

Facades and cladding

PVDF coating ACPs are widely used for exterior wall and facade cladding of commercial/residential buildings, creating a modern appearance.

Roofing

ACPs function as a reliable roofing material, offering a balance of durability and practicality for building tops.

Industruial

ACPs are used industrially for machine covers, warehouse cladding, and various other applications requiring sturdiness.

Temporary structures

ACPs’ lightweight feature makes them perfect for temporary setups like trade show structures needing easy assembly.

Interior design

In commercial and residential spaces, ACPs create decorative walls, false ceilings, dividers, and partitions for stylish interiors.

Insulation

ACPs can provide both thermal and acoustic insulation for buildings.Which improves a building’s energy efficiency.

Transportation

With excellent strength-to-weight ratio, ACPs are widely used for bus/train body panels and durable trailer cladding.

Signs and displays

ACPs’ smooth, flat surface enables high-quality graphics for indoor/outdoor signs, billboards, lightboxes, and POS displays.

Questions? We are happy to help

Contact us to get the latest quotes or customized solutions for your new projects