04 Sep Understanding ACP Panels Thickness Options in 2025

Table of Contents

You can see ACP panels on buildings, inside rooms, and on signs. The thickness of an aluminum composite panel shows how strong it is. Thicker panels are stronger and last longer. Outside walls and signs need panels that are at least 4 mm thick. The aluminum sheets should be 0.2 mm thick or more. Indoor aluminum composite panels are usually thinner. They are about 3 mm thick. This makes them look good and work well. Picking the right acp thickness helps you follow rules. It also makes things safer and work better. New trends in aluminum composite panels use better coatings. They also use stronger aluminum layers.

Key Takeaways

Pick 3mm thick ACP panels for inside walls and ceilings. These panels are light and simple to put up. They also look nice.

Use 4mm or thicker ACP panels for outside walls and signs. These panels are strong and last long. They keep people safe in bad weather.

Look for fire-resistant panels with thicker skins and special cores. These help meet safety rules. They also protect people in tall or busy buildings.

Measure panel thickness with tools like digital calipers or micrometers. Always take off any protective film before you measure.

Choose the right thickness for your project. Think about how long it will last, how safe it is, and how much it costs.

ACP Panels Thickness Options

Common Thicknesses in 2025

There are many acp panel thickness choices for projects. The most popular sizes in 2025 are 3mm, 4mm, and 6mm. These sizes work for most building and design jobs. You use 3mm aluminium composite panels inside buildings. They go on walls, ceilings, and room dividers. This thickness makes the panels light and easy to put up. You can also shape them without trouble. For outside walls, you use 4mm acp panels. This size gives good strength and looks nice. It also costs less than thicker panels. Most big buildings use 4mm aluminum composite panel. This thickness meets safety rules and standards. You pick 6mm aluminium composite panels for places that need to be very strong. These panels work well for curtain walls and busy areas. This thickness is good for large projects and rough weather.

Tip: Always check what acp sheet sizes are available before you begin. Standard sizes help you plan better and waste less material.

Here is a table that shows the most common acp sheet sizes and how people use them:

ACP Sheet Sizes | Thickness | Typical Use |

|---|---|---|

1220mm x 2440mm | 3mm | Interior walls, partitions |

1220mm x 2440mm | 4mm | Exterior cladding, facades |

1500mm x 3000mm | 6mm | Curtain walls, large panels |

You will see that 4mm aluminium composite panel is the most used. Companies make more of this thickness because it works well and saves money. You find 4mm acp panels in many buildings all over the world.

Specialized and Custom Thicknesses

Some projects need special acp panels. Top companies make aluminium composite panels from 2mm to 6mm thick. These are for signs, big buildings, and cool designs. Thin panels like 2mm or 2.5mm are for signs and displays. They are light and easy to cut. Thick panels, up to 12mm, are for places that need extra strength or fire safety. Fire-rated aluminum composite panel and panels with stone or wood look come in custom thicknesses. These meet safety and design needs. You see these panels in hospitals, schools, and tall buildings.

Acp sheet sizes and details change for each project. Custom acp panels let you pick color, finish, and fire safety level. You use these panels in places like the Middle East, Europe, and Australia. These places have special building rules.

Companies use strict checks to keep thickness the same. They measure aluminum coil thickness and use machines to make panels. Every panel gets tested. They check coating thickness, how well it sticks, and color. These steps make sure aluminium composite panels meet world standards.

Note: Always ask for acp sheet details and sizes before you buy. This helps you get the right aluminium composite panel for your job.

Thickness changes how heavy and strong acp panels are. Thicker panels weigh more and feel tougher. You get better fire safety and weather protection with thicker aluminium composite panels. Pick the thickness that fits your job and follows safety rules.

Aluminum Composite Panel Structure

Core and Aluminum Skin Thickness

Core and Aluminum Skin Thickness

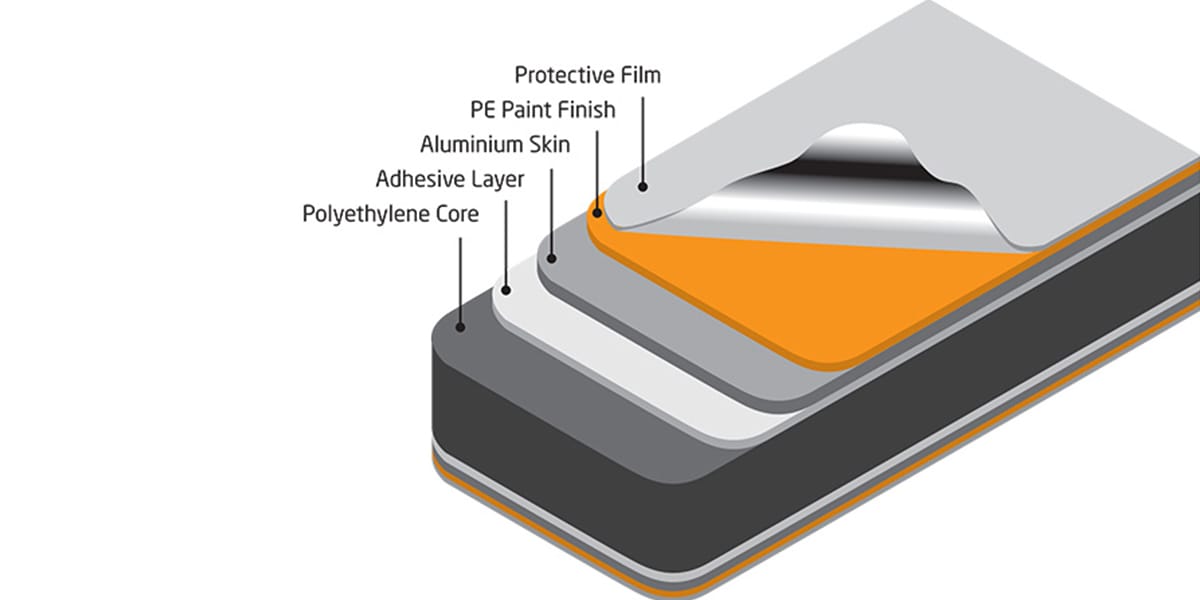

When you look at an aluminum composite panel, you see two thin aluminum sheets. There is a core in the middle. The total thickness comes from the skins and the core together. Most panels use aluminum skins that are between 0.1 mm and 0.5 mm thick. The core sits between the two skins. It is usually between 2.4 mm and 5.5 mm thick. The core can be made from polyethylene, mineral-filled material, or honeycomb aluminum. Each type is used for different jobs.

The core gives the panel most of its strength. It also helps with fire resistance.

Thicker aluminum skins make the panel stronger and more stable.

Fire-rated panels use thicker skins (at least 0.5 mm) and a mineral core for extra safety.

Here is a table to show how the thickness of each part changes with the job:

Application Type | Aluminum Skin Thickness (mm) | Total Thickness (mm) |

|---|---|---|

Exterior Wall Panels | ≥ 0.2 | ≥ 4 |

Indoor Panels | 0.1 – 0.2 | ~ 3 |

Fire-Rated Curtain Wall Panels | ≥ 0.5 | > 4 |

Note: Always check the total thickness and the core type before you pick a panel.

How Structure Affects Performance

The way an aluminum composite panel is built changes how it works. If you choose thicker aluminum skins, the panel can take more hits and is stronger. A thicker core makes the panel stiffer and helps it not bend. Fire-rated cores, like mineral-filled or honeycomb, give better fire safety.

Thicker skins (up to 0.5 mm) help the panel handle wind and bumps.

A strong core keeps the panel flat and stops it from bending.

Special cores, like honeycomb, make the panel light but still strong and safe.

The total thickness changes the weight, strength, and fire safety of the panel. You should always pick the right structure for your needs. For tall buildings or busy places, use a thicker, fire-rated panel. For indoor signs, a thinner panel with a standard core is good.

Thickness and Performance

Durability and Safety

The thickness of acp panels matters a lot. Thicker panels, like 4mm or 6mm, are stronger. They can handle bumps and keep heat out better. These panels do well in tough weather. They last through hot sun, heavy rain, and storms. Many acp panels can last 10 to 20 years or longer. Special coatings, like PVDF, protect the panels more. These coatings help panels meet fire safety rules.

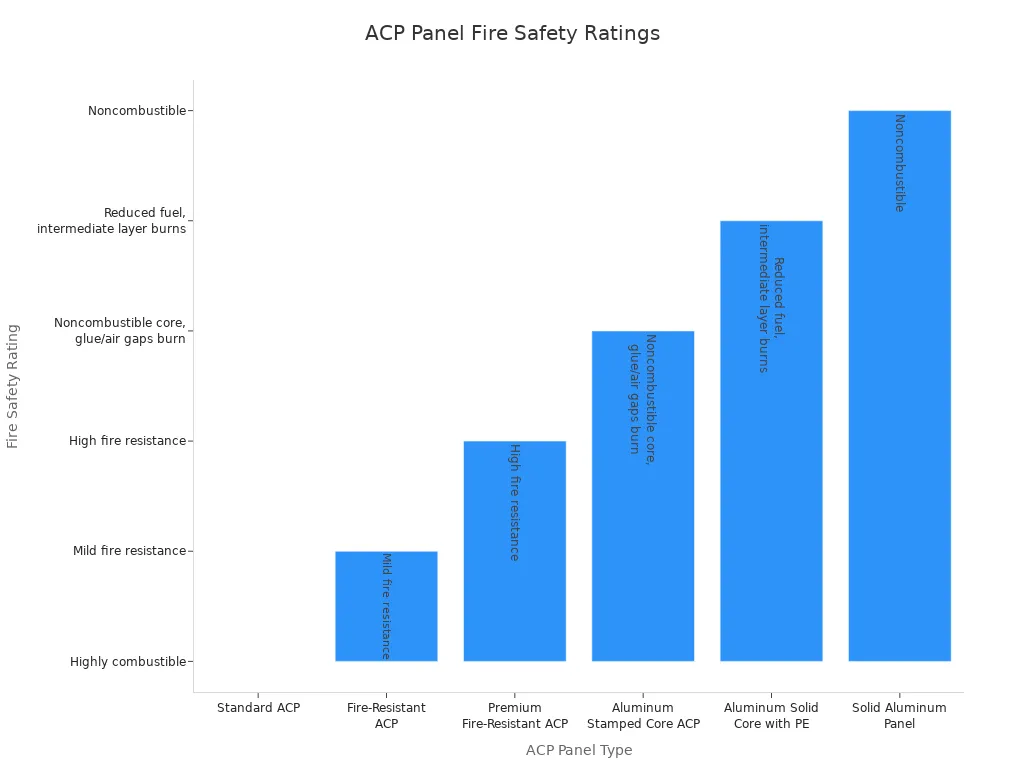

Safety is very important for every building. Thicker acp panels are stiffer and stronger. This helps buildings follow safety codes today. Fire-resistant acps have mineral-filled cores and thicker skins. These slow down fire and make less smoke. People get more time to leave safely. Always check fire safety standards before buying panels. Look for rules like EN 13501-1 or ASTM E84. Picking the right thickness and core keeps people safe and follows the rules.

Tip: Fire-resistant acps are needed for tall buildings and busy places. They help stop fires and keep people safe.

Thicker acp panels also block more noise. Fire-retardant cores help with sound and fire safety. These panels last long and need little fixing. You worry less about repairs over time.

Cost Considerations

Think about your budget when picking acp thickness. Thicker panels cost more because they use more material. Prices for acp panels go from $15 to $35 per square foot. The price depends on thickness, core, and quality. Fire-resistant acps cost 20-30% more. They give better safety and meet strict fire rules.

Thin acp panels, like 2mm, save money and are easy to put up. They work well for signs and small indoor jobs.

Thick panels, like 4mm or 6mm, need strong supports and special setup. This makes your project cost more.

Putting up panels costs $5 to $15 per square foot. You may need extra parts, like supports and fasteners, which add $3 to $7 per square foot.

Picking the right thickness helps you balance cost, safety, and how well panels work. Always check your project needs and think about saving money with panels that last and need little care.

Aluminium Composite Panels Applications

Exterior and Facade Uses

Aluminium composite panels are used outside on buildings. They help protect buildings from rain and wind. These panels also make buildings look new and stylish. For most outdoor jobs, use panels that are at least 4 mm thick. This thickness gives good strength and does not cost too much. Tall buildings or windy places may need panels that are 5 mm or thicker. Make sure the aluminum skin is at least 0.5 mm thick. This helps the panel last longer and stay safe. Rules like EN 13501-1 and ASTM E84 help you pick the right panels. Look for certifications like ISO-9002 to check quality.

ACP Panel Thickness | Recommended Application Area | Notes and Characteristics |

|---|---|---|

2-3 mm | Indoor/light projects | Good for inside walls, ceilings, and room dividers; not for outside or heavy jobs. |

4 mm | Outdoor and facade applications | Works for many jobs; good for outside walls, signs, and building fronts. |

5 mm and above | High-rise curtain walls, large outdoor projects | Best for strong places; often used with thicker skins or fire-safe cores. |

Tip: Always check your local rules before picking aluminium composite panels for outside use.

Interior and Signage Uses

Aluminium composite panels are used inside for walls, ceilings, and signs. Thin panels, between 2 mm and 3 mm, work best indoors. They are light and easy to put up. You can use them for creative designs. For signs, these panels keep colors bright and last long. Pick a good finish and clean the panels to keep them nice. Most indoor panels have a 0.2 mm aluminum skin and a PE coating. This setup is safe and meets most rules for inside use.

2 mm to 3 mm panels are best for inside walls, ceilings, and room dividers.

These panels are also good for signs and displays because you can cut and shape them easily.

Always check for safety labels and fire ratings if you use panels in public places.

Curtain Walls and Specialized Uses

Some buildings need special aluminium composite panels for curtain walls or cool designs. Curtain walls use panels that are at least 4 mm thick. Each aluminum layer should be 0.5 mm thick. These panels often have a special coating to protect from weather. Sometimes, custom thicknesses like 2.5 mm or 3 mm are used for special shapes. Always pick the right thickness for your building’s needs, like wind and fire safety. For curtain walls, use panels made from strong alloys like the 3000 or 5000 series.

Application Type | Aluminum Layer Thickness (mm) | Total Panel Thickness (mm) | Coating Type |

|---|---|---|---|

Curtain Walls | 0.5 (each layer) | ≥ 4.0 | Fluorocarbon resin |

Exterior Wall Decoration & Advertising | ≥ 0.2 | ≥ 4.0 | Fluorocarbon or polyester |

Indoor Use | 0.10 – 0.20 | ~3.0 | Polyester or acrylic |

Note: Always ask for certificates and reports from the maker to make sure your aluminium composite panels are safe and strong.

The way you use aluminium composite panels depends on thickness, coating, and core type. Always pick the panel that fits your project for the best results.

Measuring ACP Panels Thickness

Tools and Methods

Tools and Methods

You need to measure ACP panels thickness before you start your project. Accurate measurements help you choose the right acp sheet sizes and avoid problems during installation. You can use several tools for this job. A digital caliper gives you quick and precise results. You place the jaws of the caliper on the edge of the panel and read the thickness on the screen. A micrometer also works well for thin panels. You turn the ratchet until it touches the panel, then check the scale for the thickness.

Some people use a thickness gauge. This tool slides along the edge and shows the measurement. You can use a ruler for rough checks, but it does not give exact numbers. Always measure at different points on the panel. This helps you spot any uneven spots or defects. You should record each measurement and compare it to the acp sheet sizes listed by the manufacturer.

Tip: Clean the panel before you measure. Dust or coating can change the reading.

Here is a table of common tools and their uses:

Tool | Use Case | Accuracy Level |

|---|---|---|

Digital Caliper | Most acp sheet sizes | High |

Micrometer | Thin panels | Very High |

Thickness Gauge | Quick checks | Medium |

Ruler | Rough estimates | Low |

Common Mistakes

You might make mistakes when measuring ACP panels thickness. One common error is using the wrong tool for the job. A ruler cannot measure thin panels well. You may also forget to check several spots on the panel. This can lead to wrong acp sheet sizes for your project. Some people measure with the protective film still on the panel. This adds extra thickness and gives a false reading.

You should avoid pressing too hard with the tool. This can bend the panel and change the measurement. Always follow the manufacturer’s instructions for installation and measurement. If you skip these steps, you may pick the wrong panel or face problems later.

Note: Always remove any film or coating before you measure. Double-check your results to make sure you have the right acp sheet sizes.

When you choose ACP panel thickness in 2025, keep these points in mind:

Check that the panel thickness matches the label using the right tools.

Pick 3mm panels for indoor use and 4mm for outdoor projects to boost durability and safety.

Look for panels with strong coatings and fire-retardant cores to meet new safety standards.

Thicker panels give more strength, while thinner ones work better for curves.

You should talk to experts or follow building codes for complex designs. New trends focus on better core materials and coatings, so you get panels that last longer and protect your building.

FAQ

What is the best ACP panel thickness for home interiors?

You should use 3mm ACP panels for most home interiors. This thickness gives you a lightweight panel that is easy to install. It also looks smooth on walls and ceilings.

How do you know if an ACP panel is fire-resistant?

Look for labels like “fire-rated” or check for certifications such as EN 13501-1. Fire-resistant panels often have a mineral core. Always ask your supplier for test reports.

Can you cut ACP panels to custom sizes?

Yes, you can cut ACP panels with simple tools like a saw or a cutter. Always measure carefully before cutting. Wear safety gear to protect your hands and eyes.

Do thicker ACP panels last longer outside?

Thicker ACP panels, like 4mm or 6mm, last longer outdoors. They resist wind, rain, and sun better than thin panels. You get more strength and safety with thicker panels.

What tools do you need to measure ACP panel thickness?

You can use a digital caliper or a micrometer for accurate measurements. A thickness gauge works for quick checks. Always clean the panel before measuring for the best results.

Core and Aluminum Skin Thickness

Core and Aluminum Skin Thickness Tools and Methods

Tools and Methods