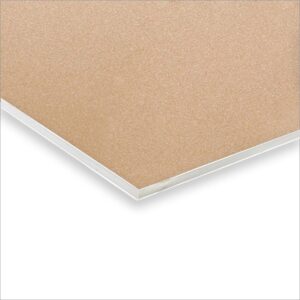

Aluminum composite panel (ACP) also known as aluminum composite material (ACM), is a lightweight, durable, and versatile construction material consisting of two thin aluminum sheets composite to a non-aluminum core, typically polyethylene or a mineral-filled material.

ACPs are widely used in various applications due to their aesthetic appeal, ease of installation, and resistance to weather and corrosion.

ACP Panel Applications

Aluminum composite panel (ACP Panel) is widely used in various fields due to its superior properties such as light weight, high strength and excellent weather resistance.

Facades and cladding

ACPs are widely used for exterior wall and facade cladding of commercial/residential buildings, creating a modern appearance.

Interior design

In commercial and residential spaces, ACPs create decorative walls, false ceilings, dividers, and partitions for stylish interiors.

Roofing

ACPs function as a reliable roofing material, offering a balance of durability and practicality for building tops.

Insulation

ACPs can provide both thermal and acoustic insulation for buildings.Which improves a building’s energy efficiency.

Industrial applications

ACPs are used industrially for machine covers, warehouse cladding, and various other applications requiring sturdiness.

Transportation

With excellent strength-to-weight ratio, ACPs are widely used for bus/train body panels and durable trailer cladding.

Temporary structures

ACPs’ lightweight feature makes them perfect for temporary setups like trade show structures needing easy assembly.

Signs and displays

ACPs’ smooth, flat surface enables high-quality graphics for indoor/outdoor signs, billboards, lightboxes, and POS displays.

Our Products

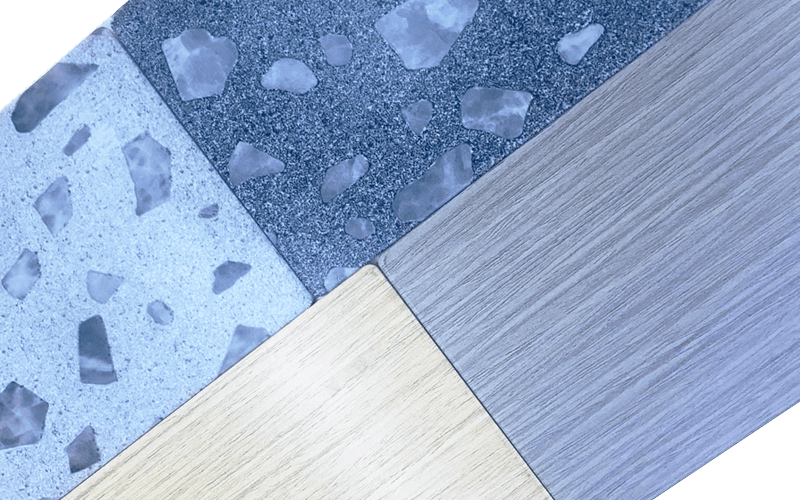

we offer types of aluminium composite panel, including regular ACP panel or fireproof ACP panel. Such as pure color and metal color ACP, marble finish ACP, wooden finish ACP and son on.

-

ACP Sheet Fireproof

-

Fire Rated ACP Sheets

-

Fireproof Aluminum Composite Panel

-

2mm Interior Aluminium Composite Panel

-

3mm Aluminium Composite Panel ACP

-

4mm Exterior Aluminium Composite Panel

-

5mm Aluminium Plastic Composite Panel

-

Interior ACP Panel PE Coating Wall Panel

-

Exterior ACP Sheet PVDF Coating

-

Non-combustible A2 aluminium composite sheet

-

B1 Fire Rated Aluminium Composite Panel

-

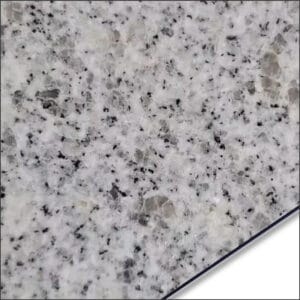

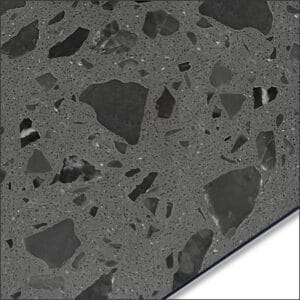

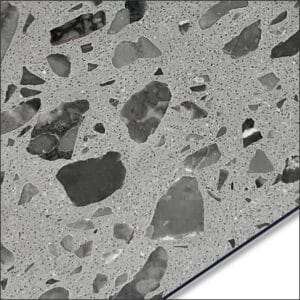

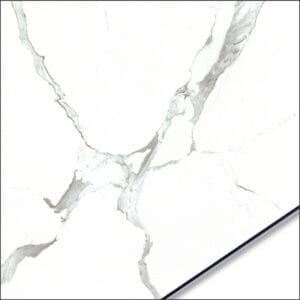

QSJ-0069 Marble ACP Sheet

-

QSJ-0068 Marble ACP Aluminium Panel

-

QSJ-0063 Marble Aluminum Composite Panel

-

QSJ-0061 Marble Composite Panel Aluminium

-

QSJ-0060 Marble ACM Aluminum

-

QSJ-0059 Marble ACM Sheets

-

QSJ-0058 marble acp panel sheet

-

QSJ-0067 marble aluminum composite sheet

-

2mm ACP Sheet For Light Box Back Side Panel

-

2mm Aluminium Composite Panel Signage

-

QSJ-0001 Wood ACP Sheet

-

QSJ-0002 Wooden Aluminium Composite Panel

-

QSJ-0003 Wooden Exterior ACP Sheet

-

QSJ-0004 Wooden ACP Aluminium

-

QSJ-0005 Wooden ACP Composite Panel

-

QSJ-0006 Wooden ACP Aluminium Sheet

Advantages of our aluminium composite panels

Lightweight

The composite structure makes ACPs significantly lighter than solid aluminum or other cladding materials, facilitating easier handling and installation.

Durability

Aluminum offers good resistance to weather, corrosion, and impact, making ACPs suitable for both interior and exterior applications.

Aesthetic Appeal

ACPs are available in a wide range of colors, finishes, and textures, allowing for diverse design possibilities

Versatility

ACPs can be cut, drilled, glued, screwed, and bent, making them adaptable for various architectural and design needs

Easy Installation

ACPs are relatively easy to install, often requiring specialized tools and techniques depending on the specific application

Long Lifespan

With proper care and maintenance, ACP sheets can have a long service life (40~60 years), reducing the need for frequent replacements.

Innovative Panel Finish Options

At ALCADEX, we offer a diverse selection of colors, finishes, and textures. Furthermore, our colorimetry laboratory enables us to reproduce any RAL or PANTONE color, or create bespoke finishes based on physical samples.

Leveraging our advanced technology in PVDF 70/30 coating application, we ensure uniform coverage and superior adhesion. This guarantees maximum resistance to aging, superior UV protection, and excellent performance throughout the machining and shaping processes of the panel.

Explore how our finishing collections can elevate your projects to unprecedented levels of excellence and distinction.

Customized Size for Your Project

Alcadex aluminum composite panels are available in four standard widths: 1220, 1250, 1500, and 1570 millimeters, with a maximum length of 6000 millimeters. We can provide aluminum composite panel solutions in various dimensions, thicknesses, and surface coating treatments according to your project requirements, all aimed at ensuring the perfection of your project.

One Stop Solutions for All The Clients

For wholesale clients, customized processing can be a significant challenge, especially for sign board clients. In addition to wholesale ACP boards, we also offer panel processing services for aluminum panels or aluminum composite sheets. These services include cutting, punching, grooving, CNC machining, and fittings for aluminum composite panels; as well as welding, anodizing, and painting for aluminum sheets.

No matter what processing services you require, we can execute them with precision.

Questions? We are happy to help

Contact us to get the latest quotes or customized solutions for your new projects